TrueVIS LG & MG Series Professional UV Printer/Cutters

-

MSRP

LG-640

$26,395 US*LG-300

$23,095 US*MG-640

$20,345 US*MG-300

$17,595 US** U.S. only. For Canada, Latin America and Caribbean pricing, please contact an Authorized Roland DGA Dealer in your area.

-

LEASE PRICE

LG-640

$535 US**LG-300

$468 US**MG-640

$413 US**MG-300

Apply Now

$357 US**

** For 60 months, OAC

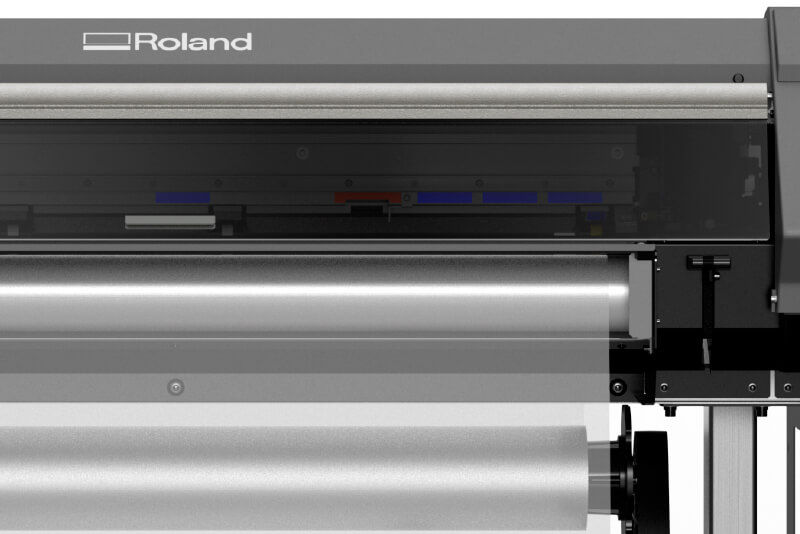

The TrueVIS LG and MG series combines the flexibility of print and cut, the benefits of UV-LED printing and TrueVIS heritage, adding a new dimension to graphics printing.

- High-definition output

- Specialty printing for textures and effects

- Broad media compatibility

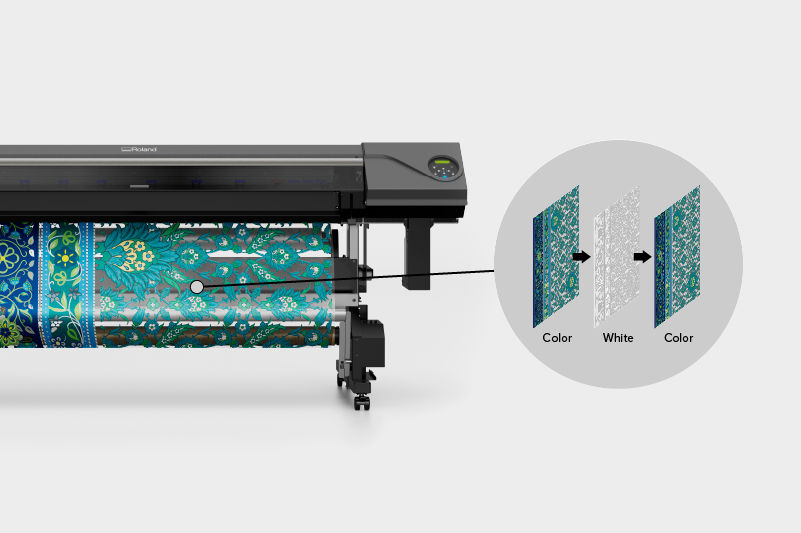

- High-density white ink

- Fast-drying prints for quick turnaround and finishing

WINNER

Keypoint Intelligence BLI Pick Award

UV Print-and-Cut Solutions

Take Print and Cut Further

TrueVIS is synonymous with industry-leading print-and-cut machines. Enhance your capabilities with the added power of premium-quality UV-LED printing technology and specialty effects capabilities to offer your customers even more products.

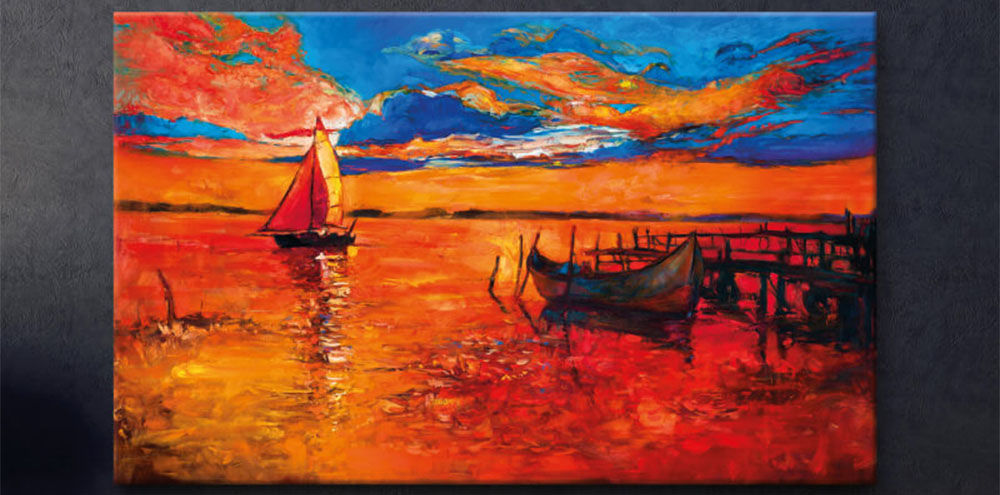

Ultimate Print Expression

The combination of ultra high-definition print technology and specially formulated UV ink lets you accurately reproduce colors in a wide color gamut.

Certified for Commercial-Grade Type II Wall Coverings

Roland DG EUV5 inks have met industry-standard Type II certifications for popular non-PVC wall covering materials*, ideal for commercial and hospitality applications.

* EUV5 ink has passed commercial-grade requirements on specific materials. For Type II certifications, testing is required on each individual material. Inquire to learn more about which materials are certified for your application.

GREENGUARD Gold

ECO-UV5 inks are GREENGUARD Gold certified, meaning they meet strict standards of low chemical emissions, making them ideal for indoor applications.

LG SeriesHigh-performance Professional Features

MG SeriesCustom Professional Features

Powerful Software Included

VersaWorks 6 included, letting you produce print-and-cut output in a simple workflow.

Low Running Cost

Long-life printheads and ink-clogging prevention ensure sustained quality.

Sheet Perforated Cut

Separate individual jobs without cutting the backing sheet for unattended long runs.

Mobile Cost Tracking

Track ink usage and more in real time with the Roland DG Connect mobile app.

Professional Color Management

Match your customers' color with ease thanks to advanced RIP features.

ICC Profiles

Access Roland DG's library of ICC profiles and find hundreds of profiles to match your needs.

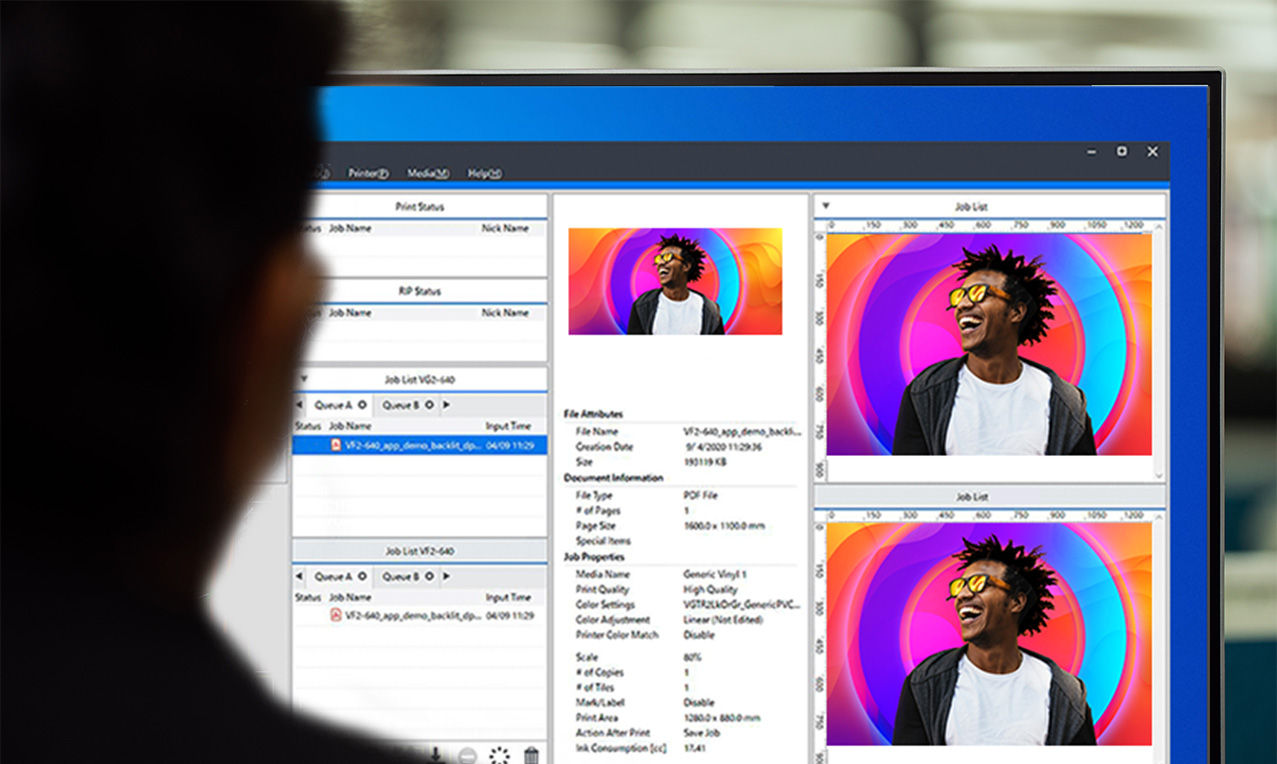

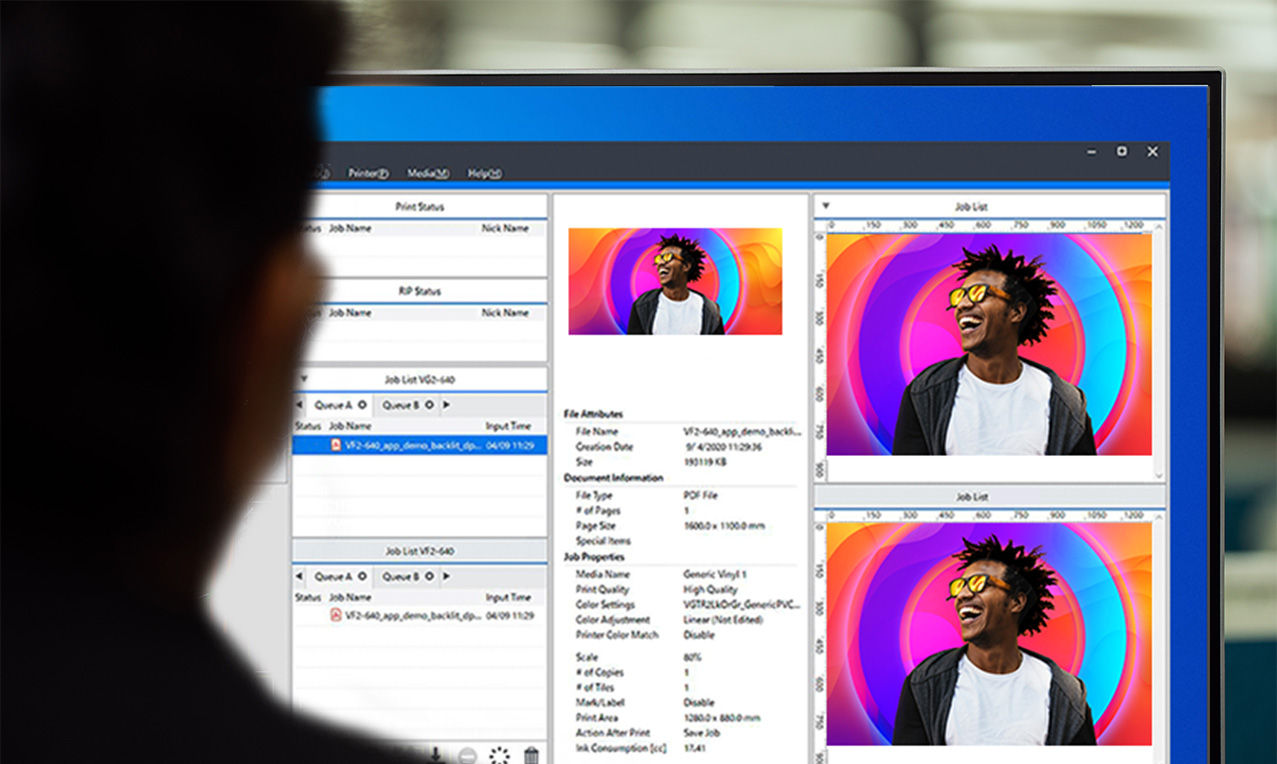

Included VersaWorks 6

RIP Software

RIP Software

The latest edition offers powerful new 64-bit processing and RIP capabilities, plus easy, nesting, cropping, tiling and other features from the world’s most popular RIP software.

- HARLEQUIN RIP dual core engine and 64-bit native processing for enhanced speed and file handling.

- Variable data options for printing multiple images and text onto media in a single print run.

- UV post cure within the RIP and auto-generate White and Gloss layers directly in the RIP with Special Color Plate Generation.

- Create cut data directly in VersaWorks 6 by extracting PDF data from your design file to use as a cut line — changing vector data into cut line data, merging multiple cut lines together, creating perf cut lines, and other intuitive features.

- Easy new drag-and-drop interface allows you to quickly add jobs to the print queue.

- Create color consistency with select Roland DG devices— print, scan and transfer color values.

- Rotate, set spacing, and maintain clip position within the RIP to give you more control when printing graphics and applying Gloss ink effects.

Roland DG Connect App

For Everything Creative

Innovative app serves as a machine-monitoring "assistant," reducing downtime, improving work efficiency, and providing you with a detailed understanding of your entire print operation to optimize overall performance.

The professional's choice for maximizing brand consistency, producing the highest quality output, and building businesses, award-winning TrueVIS printers and printer/cutters are now available in a variety of models and print production solutions to suit your specific needs. TrueVIS LG and MG series UV printer/cutters are designed for passionate print professionals like you, who seek the quality, reliability, and versatility needed to achieve new levels of success.

Roland DGA’s Industry-Leading Warranty and Support

Roland DG has provided industry professionals with the highest quality products for more than 40 years, backed by unmatched customer service and support. For even greater peace of mind, every TrueVIS LG and MG series device is supplied with a Two-Year Trouble-Free Warranty.*

* Registration within 60 days of purchase and exclusive, continuous use of Roland DG approved inks is required to qualify for the second year of warranty coverage.

Additional Information

Datasheet & Reports

Download Your LG Series Datasheet

Get your digital guide to all the features, applications, benefits and specifications of the UV Printer Cutters.

Download DatasheetDownload Your MG Series Datasheet

Get your digital guide to all the features, applications, benefits and specifications of the UV Printer Cutters.

Download DatasheetLG Series Specifications

TrueVIS LG Series

| Model | LG-640 | LG-300 | |

|---|---|---|---|

| Printing method | Piezo ink-jet method | ||

| Media | Width | 13.2 to 64 in. (335 to 1625 mm) | 7.2 to 30 in. (182 to 762 mm) |

| Thickness |

Max. 39.3 mil (1.0 mm) with liner, for printing Max. 15.7 mil (0.4 mm) with liner and 8.6 mil (0.22 mm) without liner, for cutting |

||

| Roll outer diameter | Max. 9.8 in. (250 mm) | ||

| Roll weight | Max. 99 lb. (45 kg) | Max. 66 lb. (30 kg) | |

| Core diameter | 3 in. (76.2 mm) or 2 in. (50.8 mm) | ||

| Printing / cutting width1 | Max. 62.9 in. (1600 mm) | Max. 28.9 in. (736 mm) | |

| Ink | Type | ECO-UV (EUV5P) 750 ml pouch | |

| Colors |

Eight colors (Cyan, Magenta, Yellow, Black, Gloss, White, Orange, and Red) Seven colors (Cyan, Magenta, Yellow, Black, Gloss, White, and Red) and Primer Seven colors (Cyan, Magenta, Yellow, Black, White, Orange, and Red) and Primer Seven colors (Cyan, Magenta, Yellow, Black, White, Orange, and Red) Six colors (Cyan, Magenta, Yellow, Black, Gloss, and White) and Primer Six colors (Cyan, Magenta, Yellow, Black, Gloss, and White) Four colors (Cyan, Magenta, Yellow, and Black) |

||

| Ink curing unit | Built-in UV-LED lamp | ||

| Print resolution (dots per inch) | Max. 1200 dpi | ||

| Print speeds | LG-640 343 sqft/hr at 720 × 600 dpi | LG-300 232 sqft/hr at 720 × 600 dpi | |

| Cutting speed | 0.39 to 11.8 in./s (10 to 300 mm/s) | ||

| Blade force2 | 30 to 500 gf | ||

| Blade | Type | Roland CAMM-1 series blade | |

| Offset | 0 to 59 mil (0 to 1.500 mm) | ||

| Software resolution (when cutting) | 0.98 mil/step (0.025 mm/step) | ||

| Media heating system3 | Front heater set temperature: 86 to 131 °F (30 to 55 °C) | ||

| Connectivity | Ethernet (100BASE-TX/1000BASE-T, automatic switching) | ||

| Power-saving function | Automatic sleep feature | ||

| Power requirements | 100-120/220-240 Va.c. 50/60 Hz 6.5/3.2 A | 100-120/220-240 Va.c. 50/60 Hz 5.7/2.6 A | |

| Power consumption | During operation | Approx. 800 W | Approx. 650 W |

| Sleep mode | Approx. 85 W | ||

| Acoustic noise level | During operation | 63 dB (A) or less | |

| During standby | 58 dB (A) or less | ||

| Dimensions (with stand) | 114.3 in. x 29.5 in. x 55.6 in. (2902 mm x 748 mm x 1412 mm) |

80.3 in. x 29.5 in. x 55.6 in. (2038 mm x 748 mm x 1412 mm) |

|

| Weight (with stand) | 461 lb. (209 kg) | 371 lb. (168 kg) | |

| Environment | During operation4 | Temperature: 68 to 89.6 °F (20 to 32 °C), Humidity: 35 to 80 % RH (no condensation) | |

| Not operating | Temperature: 41 to 104 °F (5 to 40 °C), Humidity: 20 to 80 % RH (no condensation) | ||

MG Series Specifications

TrueVIS MG Series

| Model | MG-640 | MG-300 | |

|---|---|---|---|

| Printing method | Piezo ink-jet method | ||

| Media | Width | 8.3 to 64 in. (210 to 1625 mm) | 7.2 to 30 in. (182 to 762 mm) |

| Thickness |

Max. 39.3 mil (1.0 mm) with liner, for printing Max. 15.7 mil (0.4 mm) with liner and 8.6 mil (0.22 mm) without liner, for cutting |

||

| Roll outer diameter | Max. 8.2 in. (210 mm) | ||

| Roll weight | Max. 88 lb. (40 kg) | Max. 55 lb. (25 kg) | |

| Core diameter | 3 in. (76.2 mm) or 2 in. (50.8 mm) | ||

| Printing / cutting width1 | Max. 62.9 in. (1600 mm) | Max. 28.9 in. (736 mm) | |

| Ink | Type |

ECO-UV (EUV5) 220 ml cartridge (white) ECO-UVS 220 ml cartridge (cyan, magenta, yellow, black, white) ECO-UV (EUV5) 500 ml cartridge (cyan, magenta, yellow, black, red, orange, gloss, primer) |

|

| Colors |

Eight colors (cyan, magenta, yellow, black, red, orange, white, gloss) Seven colors (cyan, magenta, yellow, black, red, orange, white) Seven colors (cyan, magenta, yellow, black, red, orange, white) and primer Seven colors (cyan, magenta, yellow, black, red, white, gloss) and primer Six colors (cyan, magenta, yellow, black, white, gloss) and primer Six colors (cyan, magenta, yellow, black, white, gloss) Four colors (cyan, magenta, yellow, black) Shrink solution: EUVS (CMYK and Wh) with EUV5 (Re, Or, Gl) Shrink solution: EUVS (Wh) with EUV5 (CMYK, Re, Or, Gl) Shrink solution: EUVS (CMYK and Wh) with EUV5 (Re, Pr, Gl) Shrink solution: EUVS (Wh) with EUV5 (CMYK, Re, Pr, Gl) |

||

| Ink curing unit | Built-in UV-LED lamp | ||

| Print resolution (dots per inch) | Max. 1440 dpi | ||

| Print speeds | MG-640: 150 sqft/hr at 720 × 720 dpi | MG-300: 120 sqft/hr at 720 × 720 dpi | |

| Cutting speed | 0.39 to 11.8 in./s (10 to 300 mm/s) | ||

| Blade force2 | 30 to 500 gf | ||

| Blade | Type | Roland CAMM-1 series blade | |

| Offset | 0 to 59 mil (0 to 1.500 mm) | ||

| Software resolution (when cutting) | 0.98 mil/step (0.025 mm/step) | ||

| Connectivity | Ethernet (100BASE-TX/1000BASE-T, automatic switching) | ||

| Power-saving function | Automatic sleep feature | ||

| Power requirements | 100-240 Va.c. 50/60 Hz 2.8 A | 100-240 Va.c. 50/60 Hz 2.7 A | |

| Power consumption | During operation | Approx. 250 W | Approx. 240 W |

| Sleep mode | 40 W | ||

| Acoustic noise level | During operation | 63 dB (A) or less | |

| During standby | 53 dB (A) or less | ||

| Dimensions (with stand) | 111 [W] × 31 [D] × 52 [H] in. (2819 mm [W] × 781 mm [D] × 1316 mm [H]) |

77 [W] × 31 [D] × 52 [H] in. (1945 mm [W] × 781 mm [D] × 1316 mm [H]) |

|

| Weight (with stand) | 360 lb. (163 kg) | 276 lb. (125 kg) | |

| Environment | During operation3 | Temperature: 59 to 89.6 °F (15 to 32 °C), Humidity: 20 to 80 % RH (no condensation) | |

| Not operating | Temperature: 41 to 104 °F (5 to 40 °C), Humidity: 20 to 80 % RH (no condensation) | ||

Sample Request

To receive a free print sample from the LG and MG series, complete the form below and click Submit.