UV Print Powers Prototyping, Production, and Packaging for Turnup Games

Turnup Games | Waterloo, Ontario

Leanne Gray and Iles Guran really like to play games. So much so that in 2021, this husband-and-wife team launched Turnup Games in Waterloo, Ontario. They design, prototype, and produce puzzles and games in-house, calling their business a “workshop to tabletop” game company.

We talked with Leanne and Iles about what it takes to start a design, prototyping, and production business, how they handle these different aspects in-house, and what they have on the drawing – and playing – board these days.

Is there a particular game that was the foundation for Turnup Games?

Leanne Gray: Iles and I have been designing and producing products together for more than 10 years. We create games that are timeless, thoughtful, and fun for all. In 2021, we started Turnup Games and launched our first game, SUM8™, on Kickstarter. It surpassed our funding goal by more than 700 percent. SUM8 is a two-player tile-based, puzzle-like strategy game with a rearrangeable board, unique tile design and high “replayability.”

“The LEF2-300’s size, capabilities and price point fit our shop well.”

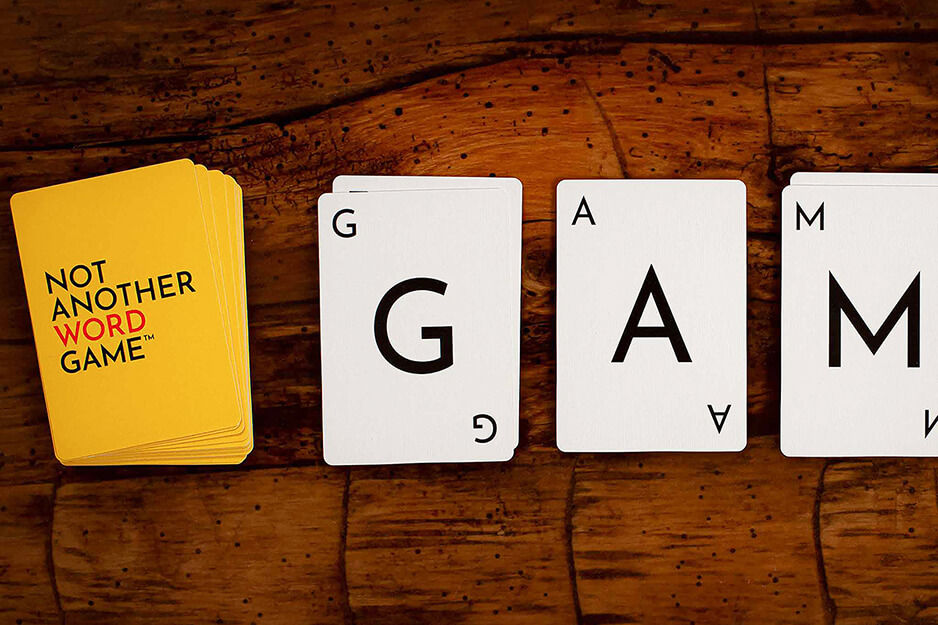

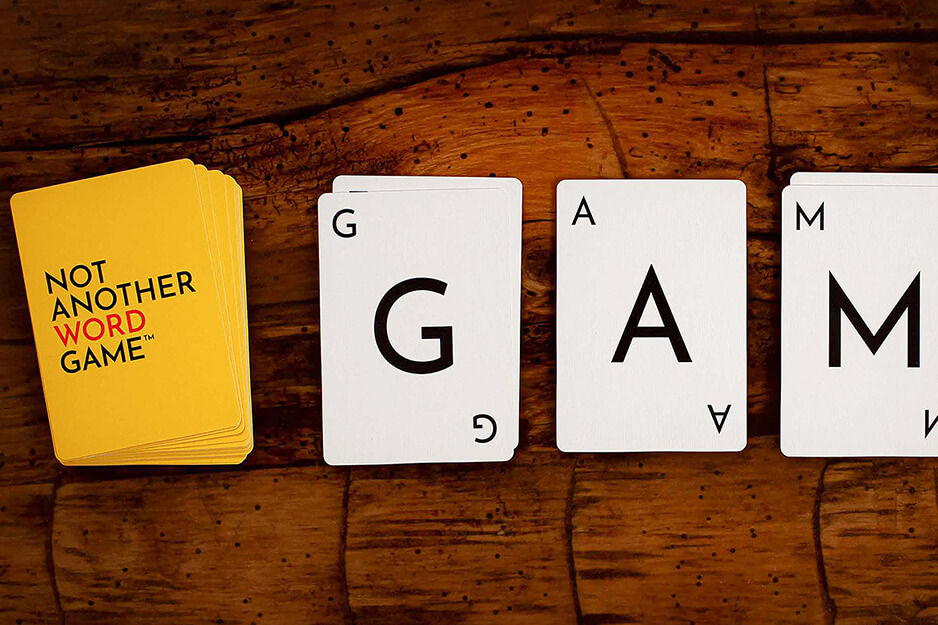

Our next game, HEXX™, a Scrabble-like word game, will launch on Kickstarter later this year. We have a variety of additional games and puzzles in the works that we’ll launch soon, including Not Another Word Game™, Five Frogs and a Log™, Splitting Heirs™, A Balanced Diet™, and Bag-O-Bones™.

Please tell us about your facility.

Iles Guran: Our 1,000-square-foot workshop in Waterloo, Ontario, is equipped with a variety of tools and machines to help with the design, prototyping, and short-run production of our tabletop games, including a Roland DG LEF2-300 benchtop UV printer, a milling machine, a laser cutter/engraver and a 3D printer. We also have a variety of hand tools and workstations for production and assembly work.

Are you seeing any trends in game design?

Iles: We’re seeing a real yearning for quality, not only in terms of design and aesthetics, but also in terms of materials and craftsmanship. The board game and tabletop game industry is quite competitive and most manufacturing is done overseas these days.

We’re also seeing an opportunity for smaller scale production games that incorporate unique components as well as higher quality materials. Shorter run production allows us to do things that larger game publishers simply can’t.

In terms of their design, what sets your games apart?

Leanne: We focus mainly on developing word, puzzle, or abstract strategy games, typically aimed at one or two players. We’ve noticed that there’s a real lack of fun and interesting one-to-two player games in the industry, even though there is strong demand for such offerings.

In addition, we make our games easy to learn and highly replayable. Beyond that, our games are extremely high-quality and unique.

Do you sell your games online?

Leanne: Yes. Our current model focuses on crowdfunding to launch a particular game or series of games, producing the quantity that gets backed, and then launching the next game.

Since we make most of our game components in-house, we can continue to sell all the games that we develop without storing a large inventory. We can also quickly add new games and ideas without the traditional overhead of mass-production.

Why did you decide to add UV print capability?

Iles: Having in-house direct-to-object printing capabilities allows us to explore rapid prototyping and to create on-demand short-run tabletop games. In addition, this versatile technology allows us to produce product packaging, game demos for review and playtesting, and marketing pieces for trade shows and direct mail.

How did you select your UV flatbed printer?

Iles: I have more than 20 years of experience in graphic design and large-format printing, so I was very focused on finding a manufacturer with a reputation for quality and reliability. Since we’re a smaller company that doesn’t have redundancy in most of our equipment, we need technology that has a proven track record of consistent, high-quality production. Roland DG’s LEF UV printer fits that bill perfectly.

In addition, the LEF2-300’s size, capabilities and price point fit our shop well. The increased speed of the 300 vs. the 200 was a real selling point for us, as was the low cost of printing and long-term ownership.

We also appreciated having matte and gloss ink options, which we use quite regularly in our design/prototyping processes. Now we can create components that would otherwise be very expensive to produce in the lower quantities of 1 - 500 units that we typically require.

We’ve had the LEF2 for almost a year and it handles anything we throw at it with ease. The print quality is very good and, with regular maintenance, we can count on this inkjet to perform well at all times. We have been able to design custom jigs to hold smaller parts and to align multi-job processes that make our production even easier.

How do you go about developing a game?

Iles: Leanne continually comes up with a wide range of ideas that we post on our “idea board.” Next, Leanne and I work together to define a more detailed version of the game or games. We develop themes, characters, moods, colors, and the overall “feel.”

From there I work to create visuals and graphic assets to bring the game into the first-off stage. This can be anything from simple hand-drawn paper mockups to fully 3D-printed and machined components to get a feel for the game. We work continually on this process until we have a “game idea” that feels right. It typically takes about three months from the initial idea to a fully playable game, although additional time is sometimes required to finalize production processes and methods.

What lies ahead for Turnup Games?

Leanne: Beyond developing our own high-quality games, we’re partnering with a couple of designers to help them bring their games to market. We’re working on a co-design (and potentially co-development) model that allows us to offer our services to others looking to introduce new games, using our capabilities and experience to help them.

We’re constantly looking for ways to share our products, and having in-house prototyping and production capability is a big part of our success. Desktop and board games are a great way to bring people together to enjoy quality time – from extremely simple to highly involved, there’s literally a game out there for everyone.