Yale School of Architecture Instructs Students with MDX Milling Technology

Yale School of Architecture

As an architect, John Eberhart loves seeing design come alive. He is a critic in the Yale School of Architecture as well as owner of a firm specializing in high-end residential and light commercial architecture. In his classes, students are given the opportunity to create their designs on Roland DG MDX milling machines.

“The Roland DG mill was the first piece of equipment we bought back in ‘01,” said Eberhart. “I taught an entire class around that piece.” Currently, the School of Architecture owns a Roland DG MDX-650 and two MDX-540s to keep up with demand. The devices are located in the School of Architecture fabrication shop along with woodworking equipment and larger CNC mills.

The fabrication shop is available to all of Yale’s architecture students, a group comprised of 200 graduate and 50 undergraduate students. Up to 25 students can use the shop at a time. “At midterms and finals, the Roland DG mills are completely booked for weeks,” said Eberhart. “Everyone was very happy when the third MDX arrived.”

Most students begin their coursework without ever having used milling machinery. “Roland DGs are great because a student with absolutely no machining experience can walk up to the machine and begin making parts with very little training or supervision,” said Eberhart. At the beginning of his courses, Eberhart leads a short tutorial session and within 2-3 hours students can begin milling projects on their own. “I wish the rest of our machines were as easy to use as the Roland DGs,” said Eberhart.

“I wish the rest of our machines were as easy to use as the Roland DGs,” said Eberhart.

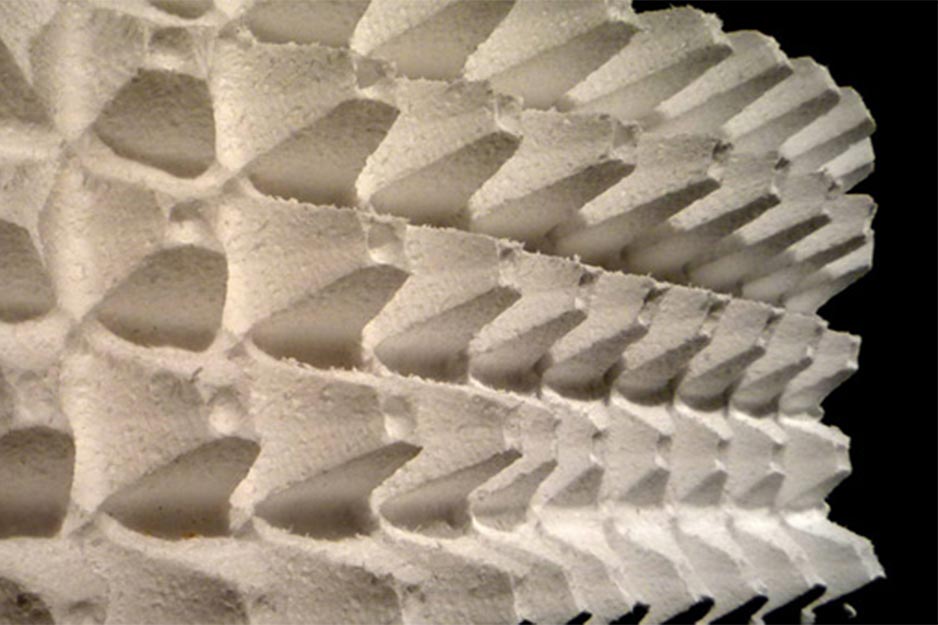

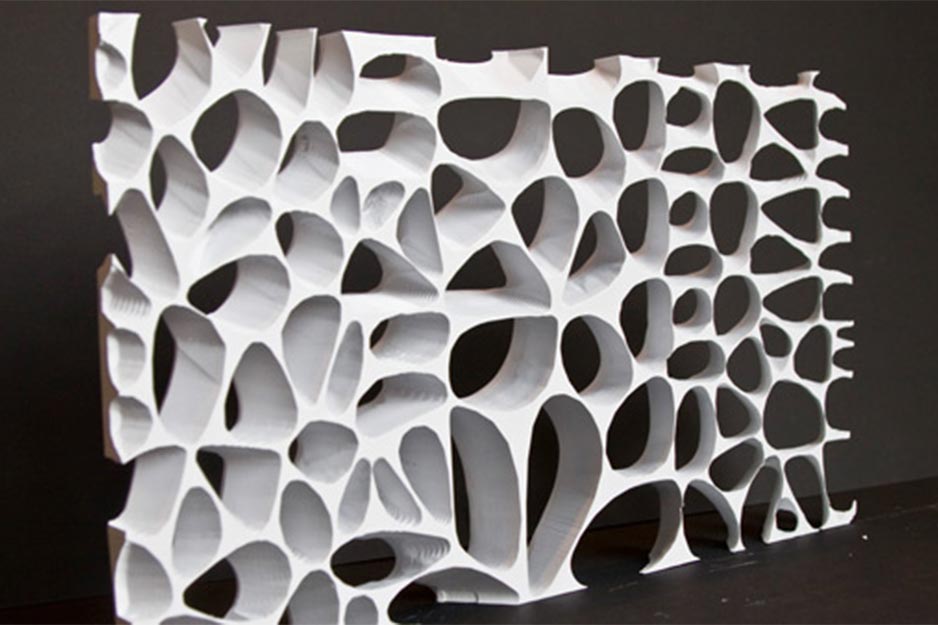

Eberhart attributes the mills’ ease of use to Roland DG’s unique software and hardware pairing. Roland DG’s mills come equipped with SRP Player CAM software that utilizes wizards to automate the prototyping process and to quickly and precisely generate tool paths. The program also provides uniform 3D scaling and support for 4-axis milling. After all the data is entered, the software generates a simulation of the finished 3D parts, allowing the machine operator to review the prototype on screen before it is milled. The result is faster prototype production, tighter dimensional accuracies and a smooth finish. “It is a great system,” said Eberhart. “The software takes out all the guesswork and runs the machine.”

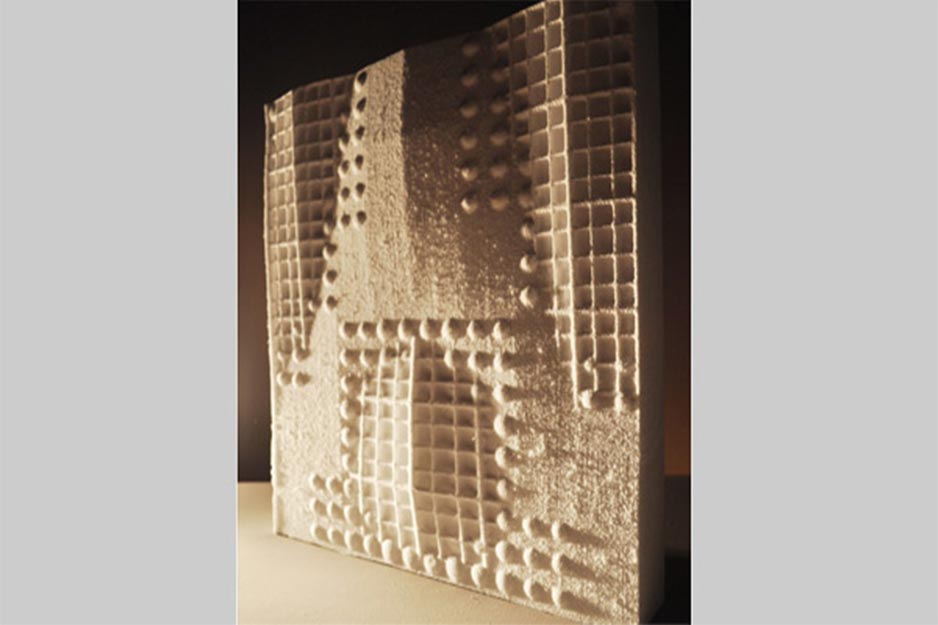

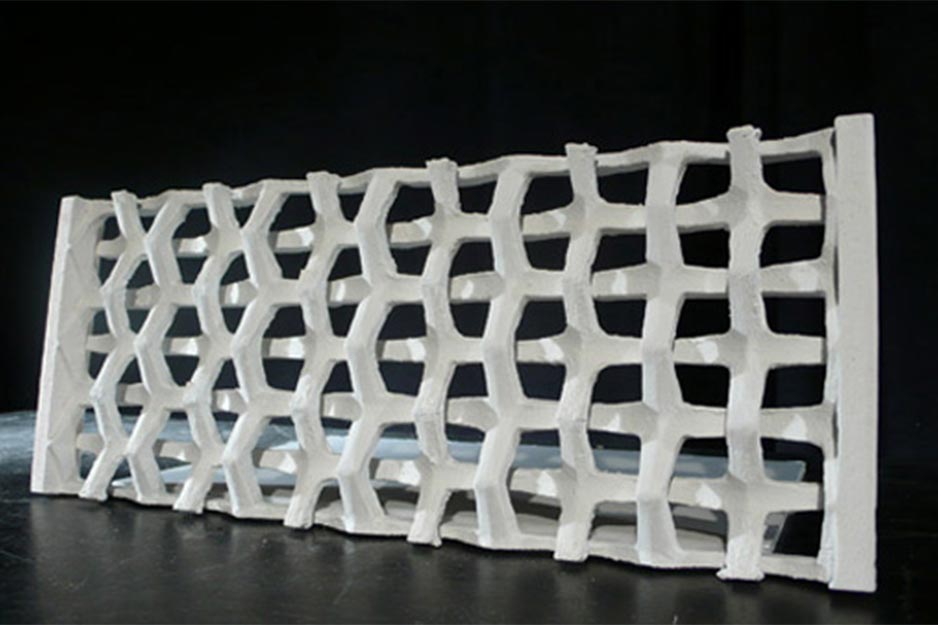

Students use the fabrication shop to produce projects for a variety of courses, including design studios, furniture design courses, product use courses, and architectural and industrial design courses. For smaller-scale projects, the MDX machines are often used to generate the final project. For larger and more complex projects, students typically use the milling machines to produce a 3D model of the design, practicing the cuts they will need to make on the CNC mills. They can also use the MDX to mill a jig for the larger equipment, as well as to practice doing flip processing.

Eberhart appreciates the safety features of the Roland DG milling machines. Unlike the other machines in the facility, students are allowed to walk up and use the Roland DGs without direct supervision 24 hours a day. To minimize accidental damage, Eberhart inserts a board of “sacrificial” plywood between the piece the students are milling and the machine. “The safety features are excellent. The torque sensors and load feedback are so good, they can run unattended,” said Eberhart. “We’ve built literally thousands and thousands of jobs, with novices handling the machines, and we’ve never had a problem.”

Eberhart credits the MDX mills with opening the use of rapid prototyping technology to a vastly wider audience. “The ease of use makes the whole field accessible to people who would never go there because of the intimidation factor,” said Eberhart. “The impact of this technology on the kinds of courses we can offer and the level of sophistication we can provide has been huge.”