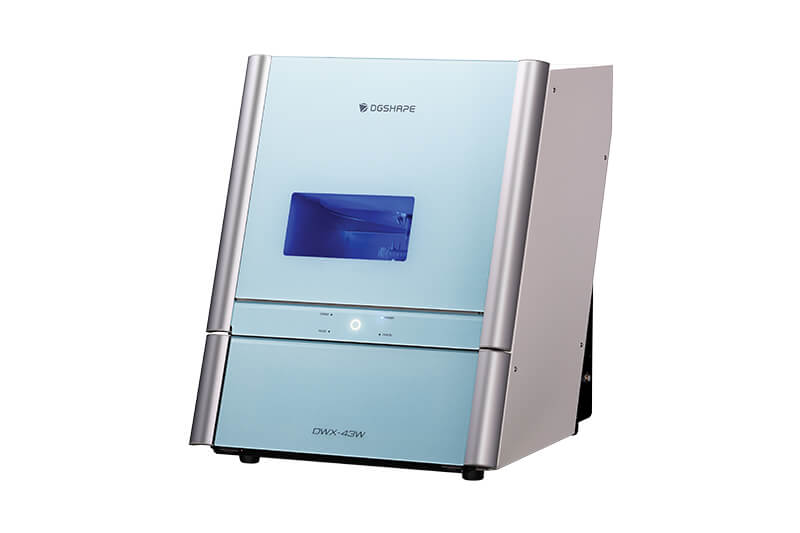

Introducing the

New DWX-43W

Wet Milling Solution

with Filter-Free Innovation!

NEW DWX-43W Wet Milling Solution

-

MSRP

$32,995 US*

* U.S. only. For Canada, Latin America and Caribbean pricing, please contact an Authorized Roland DGA Dealer in your area.

-

LEASE PRICE

$669.80 US**

Apply Now

** For 60 months, OAC

DGSHAPE’s introduction of the DWX-43W wet milling solution brings faster milling times for traditional ceramics and custom titanium abutments while reducing operating costs and increasing ROI.

- Faster Milling Times

- No More Costly Filters

- Reduced Routine Maintenance

- Expanded Milling Capabilities Built-In

- DGSHAPE CAM Software and Bonus Tooling Included

The New DWX-43W is All-Mill-All-Gain!

Faster Milling Times

Reduce the Cost of Use..."NO Filters Required!"

Increased Productivity Means Increased ROI!

Hot off the "Mill"... New DWX-43W comes with Perks!

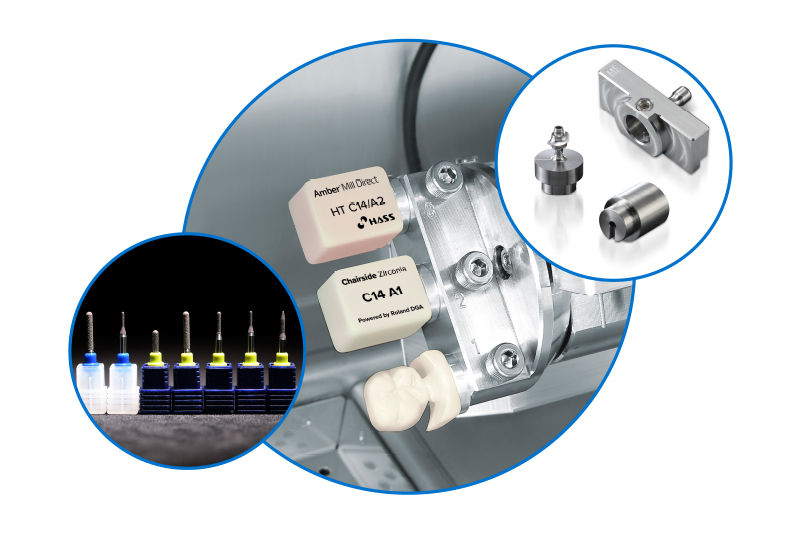

- Added Value: Includes a total of 15 authentic DGSHAPE wet milling tools for greater ROI and get you up and milling.

- New internal material adapter and coolant tank tray designs are compatible with the AK-1 Material Adapters (AK-1-ME, AK-1-DE, AK-1-GE) for milling of Custom Titanium Abutments with pre-mill blanks from MEDENTiKA®, DESS®, and GeoMEDI®.

- Mill 6 units at a time with the 6-pin material adapter (#ZV-42W) accessory for expanded milling capabilities and productivity. - Now Included.

Open-Architecture Eco-System Platform

Any Scanner → Any Software → DWX-43W

Your Choice of Restorative Materials

The Open-Architecture ecosystem of the DWX-43W allows users the flexibility to utilize their choice of restorative materials, scanner, and CAD Design Software. Users can customize a workflow that is truly built to build their business.

A Mill That Fits Your Needs

High Production Lab

- Expand production by adding a standalone wet-milling option, designed for glass ceramic and composite resin materials

- Get the same open architecture flexibility and high-quality performance as DGSHAPE dry mills, in a wet-milling configuration

- Offer on-demand production of high-esthetic, dental prosthetics

![]()

Clinicians, In-House Labs, & DSOs

- Offer your patients a same day service with ultra-accurate prosthetics – produced with an easy-to-operate machine and simplified workflow

- Open architecture allows seamless integration with existing scanning devices

- Enable chairside restoration for you and your patients with a solution that integrates with your workflow and the needs of your business

![]()