SRM-20 Compact Mill & Engraver Solution

-

MSRP

SRM-20: $4,945 US*

Engraving Accessory Kit: $763.99 US** U.S. only. For Canada, Latin America and Caribbean pricing, please contact an Authorized Roland Dealer in your area

The SRM-20 Compact Mill paired with the Engraving Accessory Kit makes it an ideal solution for small, simple, and affordable production of everything from plastic signs and awards, to diamond scribed gifts and custom circuit boards. The compact size fits into any home, office, or classroom desktop environment, while included software and accessories make it easy to get started. The Engraving Kit can be added to an existing SRM-20 or purchased together to start engraving right out of the box.

Optional Engraving Accessory Kit

Expand the SRM-20’s capabilities to include diamond scribing and rotary engraving, ideal for applications like name tags, PCB boards, gifts marking, serial plates, and more. The SRM-20 engraving kit includes:

Engrave and Mill Products

from Your Desktop

A wide range of materials, including plastic, wood, foam, acrylic, ABS, PC boards and more can be precision milled and engraved using the SRM-20 small engraving machine and engraver kit.

Precision and Productivity

Multi-axis milling is as easy as X, Y and Z

Productivity Features

| Powerful Spindle Motor |

|

|

G-Code Compatible |

|

| Maximum Axes Operation: 8”(X) x 6”(Y) x 2.38”(Z) |

|

Independent Collet System |

|

| Bundled SRP Player Software |

|

| Versatile Tooling Options |

Additional Information

Request A Call

Datasheet

Download Your SRM-20 Brochure

Get your digital guide to all the features, applications, benefits and specifications of the Desktop Milling Machine.

Download BrochureSpecifications

| MODEL | SRM-20 |

|---|---|

| Cuttable Material | Modeling Wax, Chemical Wood, Foam, Acrylic, Poly acetate, ABS, PC board |

| X, Y, and Z Operation Strokes | 8 (X) x 6 (Y) x 2.38 (Z) inches, 203.2 (X) x 152.4 (Y) x 60.5 (Z) mm |

| Workpiece table size | 9.14 (X) x 6.17 (Y) inches, 232.2 (X) x 156.6 (Y) mm |

| Distance From Collet Tip to Table | Maximum, 5.15 in (130.75mm) |

| Loadable Workpiece Weight | 4.4 lbs (2kg) |

| X-, Y-, and Z-Axis Drive System | Stepping motor |

| Operating Speed | 0.24 – 70.87inch/min, 6 – 1800mm/min |

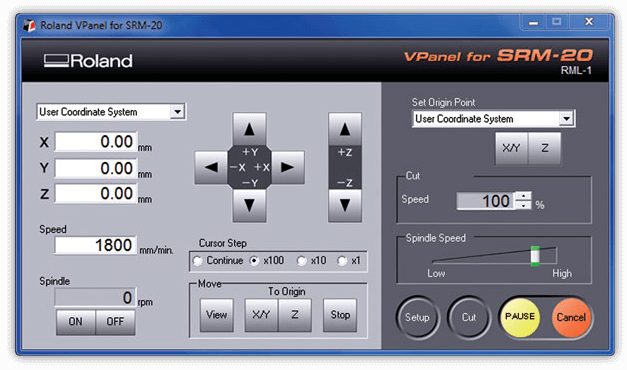

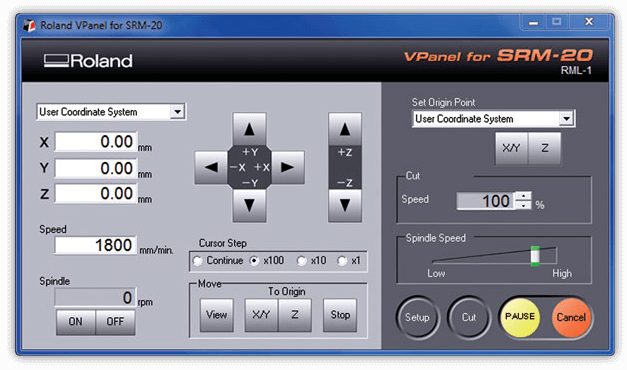

| Software Resolution | 0.000039 inches/step (RML-1), 0.000039 inches/step (NC code), 0.01 mm/step (RML-1), 0.001mm/step (NC code) |

| Mechanical Resolution | 0.0000393 inches/step, 0.000998594 mm/step |

| Spindle Motor | DC motor Type 380 |

| Spindle Rotation Speed | Adjustable 3,000 – 7,000 rpm |

| Cutting Tool Chuck | Collet method |

| Interface | USB |

| Control Command Sets | RML-1, NC code |

| Power Requirements | Machine: DC24V, 2.5A, Dedicated AC adapter: AC 100-240V ±10%, 50/60Hz |

| Power Consumption | Approx. 50W |

| Operating Noise | During operation: 65 dB (A) or less (when not cutting), during standby: 45 dB (A) or less |

| External Dimensions | 17.76 (W) x 16.80 (D) x 16.78 (H) inches, 451.0 (W) x 426.6 (D) x 426.2 (H) mm |

| Weight | 43.2 lbs, 19.6 kg |

| Installation Environment | Temperature of 41 to 104 °F (5 to 40°C), 35 to 80% relative humidity (no condensation) |

| Included Items | USB cable, AC adapter, Power cord, Collet (6mm, .236 inches), Collet set screw, Spanners (7,10mm / 0.28, 0.39 inches), Hexagonal wrench (size 2,3 mm / 0.059, 0.12 inches), Positioning pins, Double-sided tape, Start-up page guidance card, Cutting tools not included. Imperial sized collets and cutting tools not included. |

| System Requirements | |

|---|---|

| Operating system (OS) | Windows 7/8/8.1 (32-bit/64-bit edition)* |

| CPU | Intel® Core 2 Duo or more (Core i5 or more recommended) |

| Memory (RAM) | 1GB (2GB or more recommended) |

| Video card and monitor | A resolution of 1,280x1,024 or more recommended |

| Free hard-disk space required as a working space |

100 megabytes or more recommended |

| Other requirements | Internet connection and web browser, Internet Explorer version 10 or more recommended |