Inked Vinyl: Keep Calm and Wrap On

Inked Vinyl | Naples, Florida

Mark Unland, co-founder of Inked Vinyl in Naples, Florida, is a respiratory therapist by training. In fact, he recently returned to the hospital he once worked at to offer his expertise during the COVID-19 crisis.

We caught up with Mark to talk through his journey from medical professional to sign professional, how he has grown his business from the ground up, and how Inked Vinyl has maintained its focus on wraps.

You started your career as a respiratory therapist. What drew you to the signmaking industry?

Mark Unland: I’ve always enjoyed creativity in all its forms. After many years in healthcare, I was looking for a change and had identified the sign industry as both a creative and a business opportunity.

In 2014, my first business partner, Jason Norman, and I started doing our research on the sign industry and determined that, while there were lots of sign shops at that time, not many specialized in wraps work exclusively. Wraps are really creative, and focusing on that kind of application seemed like a good match for our interests.

How did Inked Vinyl get started?

To see if our plan of starting a wrap business was a good idea, we reached out to Mario Perez at Wake Graphics in Austin, Texas. Mario helped us figure out that our business could definitely work. In our area, there were only about four real competitors. Further down the road, in Miami or Tampa, there would be a lot of competition, but here in Naples, we just had to create a footprint.

At first, it was crazy how many hours it took us to do a wrap. Our lack of experience at the very start almost put us out of business, but eventually we taught ourselves what we needed to know about lamination, and later graphic design. Later still, we decided that we needed our own large-format printer.

How did you select your print production technology?

We were almost ready to buy another brand of printer, but then someone from the wrap industry said we should really look at Roland DG’s printers. We took a step back, reached out to sales reps, and started watching what other people were using. It seemed like the Roland DG models offered outstanding versatility and reliability.

We got our first Roland DG inkjet, a SOLJET, at Florida Graphics Supply. It has performed amazingly well. We still use it – it’s a true workhorse.

Eventually, we had so many print jobs to run, we couldn’t keep up with just one printer. We realized that we needed to add a second machine. That’s when we purchased our TrueVIS VG2-640 printer/cutter. It’s an amazing device – we love the color pops we can get with the wider color gamut. In addition, the VG2 prints even faster and we can laminate sooner, which really increases the total number of projects we can turn around.

How do you make people aware of your work?

We dove into the whole social media thing. We like posting the work we’ve done, but sometimes it’s hard to keep up. Because of the time it takes to post, if you just look at our feed, we look slow when we’re busy and busy when we’re slow.

Beyond promotion through social media, we don’t do any advertising. Zero. It’s essentially word of mouth. Our door swings and our phone rings.

What are some of the pointers you’d offer to others thinking about starting a wrap business?

Don’t cast your net too widely. In year two, we thought we’d add a revenue stream by offering another application besides vehicle wrapping. After buying a specialized printer, we realized that there wasn’t enough demand to justify the purchase. So, our idea turned out to be a big flop. We quickly learned that focusing solely on wraps made the most sense for us. If an existing client needs a sign, we’ll run it for them, but we really try to stick to what we do best.

What type of facility and staffing do you have now?

We have a great 2,600 square-foot location in a cool little square near an industrial park. Our storefront has 600 square feet of showroom area. We’ve added a lot of life to the room with large wall wraps of graffiti and other types of fun street art. We have a crazy long conference desk where we do our design, a production room, and a 1,500 square-foot installation bay that is decorated with a 38’ mural.

We like to say, ‘we specialize in bringing your ideas to life.’ We have ten total employees, including myself and my business partner, Robert Ivany.

What industries do you serve?

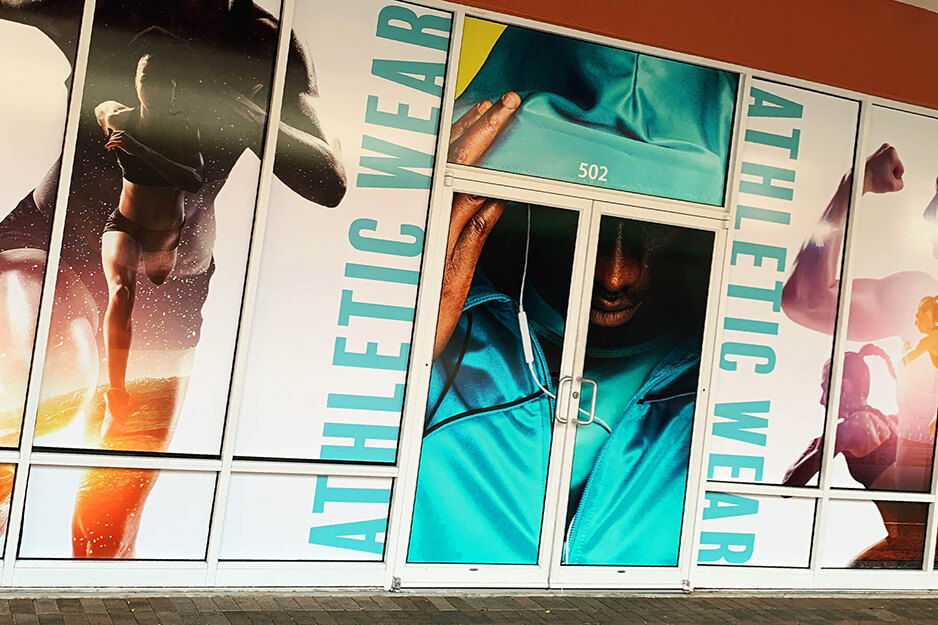

We do a lot of work for the retail industry and the construction business, restaurants, some medical facilities, and a lot of hotels. At hotels, we often put graphic designs on the inner walls of elevators, as well as on doors and windows. We also produce window wraps for the popular Miromar Outlet Mall. There are about 250 panel windows there. When a vendor leaves, we panel and print graphics for the windows.

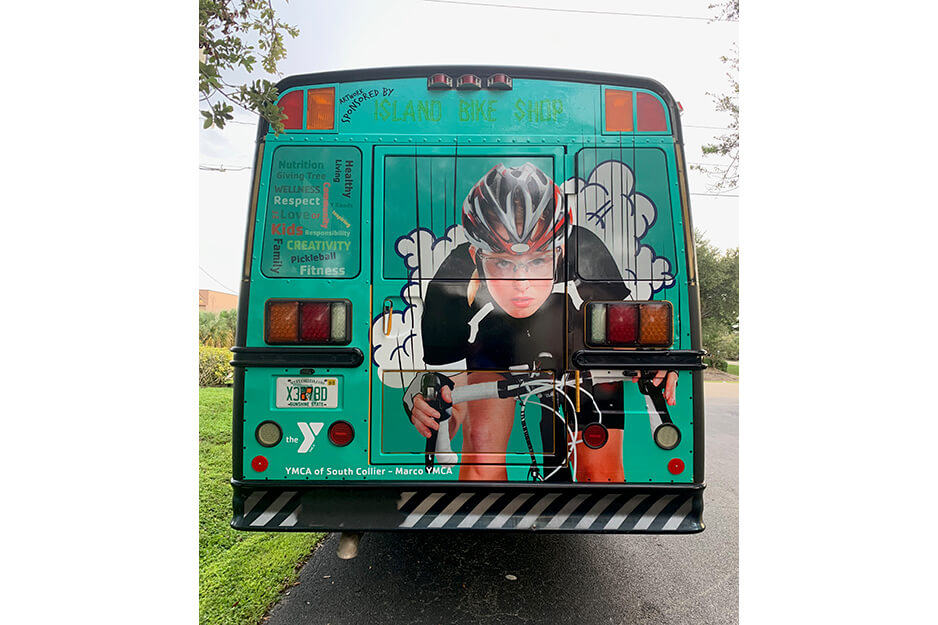

We’ve wrapped all kinds of vehicles from Mini Coopers to utility trucks – we even did some lift trucks for a construction company. We do fleet wraps of anywhere from one to 30 or more vehicles. We wrap a lot of personal vehicles and boats as well. We also design, produce and install boat wraps for Marine Max in both their Naples and Fort Myers locations.

How has COVID-19 affected your business? Are you starting to see a return to normal?

Robert came on as my business partner in November 2019, and at that point, he knew us for what he saw on paper. He didn’t know the literal storms that we’ve weathered. As the pandemic started, he worried that our business would die. I had more confidence – we’d already made it through the hurricane and a full two-week closure. We had zero business then, but people came back on the schedule when the lights came on.

When the pandemic started, I told Robert that we’d see our wrap business slow down, but that we’d still be printing banners and magnets. Fortunately, we qualified for a PPP loan, and we were able to hit the ground running.

You’ve rejoined the hospital to help out during the pandemic. How is that going?

In March of 2020, I went back to work at the hospital on the weekends. My specialty, respiratory therapy, was especially needed due to COVID-19. I’ve maintained some shifts at the hospital throughout the year, and with help from everyone, we’ve been able to keep Inked Vinyl running full speed. One thing’s for sure – it’s been a crazy year.

We caught up with Mark to talk through his journey from medical professional to sign professional, how he has grown his business from the ground up, and how Inked Vinyl has maintained its focus on wraps.

You started your career as a respiratory therapist. What drew you to the signmaking industry?

Mark Unland: I’ve always enjoyed creativity in all its forms. After many years in healthcare, I was looking for a change and had identified the sign industry as both a creative and a business opportunity.

In 2014, my first business partner, Jason Norman, and I started doing our research on the sign industry and determined that, while there were lots of sign shops at that time, not many specialized in wraps work exclusively. Wraps are really creative, and focusing on that kind of application seemed like a good match for our interests.

How did Inked Vinyl get started?

To see if our plan of starting a wrap business was a good idea, we reached out to Mario Perez at Wake Graphics in Austin, Texas. Mario helped us figure out that our business could definitely work. In our area, there were only about four real competitors. Further down the road, in Miami or Tampa, there would be a lot of competition, but here in Naples, we just had to create a footprint.

“[The VG2-640 is] an amazing device – we love the color pops we can get with the wider color gamut.”

Mario asked me, ‘What do you want to do?’ I told him that I wanted to do it all – design, print, and install. Our goal was to be a one-stop shop. He said he’d help us get started, and we opened our doors in January 2014. Our first wrap is still on the street – in fact, we still see it sometimes.At first, it was crazy how many hours it took us to do a wrap. Our lack of experience at the very start almost put us out of business, but eventually we taught ourselves what we needed to know about lamination, and later graphic design. Later still, we decided that we needed our own large-format printer.

How did you select your print production technology?

We were almost ready to buy another brand of printer, but then someone from the wrap industry said we should really look at Roland DG’s printers. We took a step back, reached out to sales reps, and started watching what other people were using. It seemed like the Roland DG models offered outstanding versatility and reliability.

We got our first Roland DG inkjet, a SOLJET, at Florida Graphics Supply. It has performed amazingly well. We still use it – it’s a true workhorse.

Eventually, we had so many print jobs to run, we couldn’t keep up with just one printer. We realized that we needed to add a second machine. That’s when we purchased our TrueVIS VG2-640 printer/cutter. It’s an amazing device – we love the color pops we can get with the wider color gamut. In addition, the VG2 prints even faster and we can laminate sooner, which really increases the total number of projects we can turn around.

How do you make people aware of your work?

We dove into the whole social media thing. We like posting the work we’ve done, but sometimes it’s hard to keep up. Because of the time it takes to post, if you just look at our feed, we look slow when we’re busy and busy when we’re slow.

Beyond promotion through social media, we don’t do any advertising. Zero. It’s essentially word of mouth. Our door swings and our phone rings.

What are some of the pointers you’d offer to others thinking about starting a wrap business?

Don’t cast your net too widely. In year two, we thought we’d add a revenue stream by offering another application besides vehicle wrapping. After buying a specialized printer, we realized that there wasn’t enough demand to justify the purchase. So, our idea turned out to be a big flop. We quickly learned that focusing solely on wraps made the most sense for us. If an existing client needs a sign, we’ll run it for them, but we really try to stick to what we do best.

What type of facility and staffing do you have now?

We have a great 2,600 square-foot location in a cool little square near an industrial park. Our storefront has 600 square feet of showroom area. We’ve added a lot of life to the room with large wall wraps of graffiti and other types of fun street art. We have a crazy long conference desk where we do our design, a production room, and a 1,500 square-foot installation bay that is decorated with a 38’ mural.

We like to say, ‘we specialize in bringing your ideas to life.’ We have ten total employees, including myself and my business partner, Robert Ivany.

What industries do you serve?

We do a lot of work for the retail industry and the construction business, restaurants, some medical facilities, and a lot of hotels. At hotels, we often put graphic designs on the inner walls of elevators, as well as on doors and windows. We also produce window wraps for the popular Miromar Outlet Mall. There are about 250 panel windows there. When a vendor leaves, we panel and print graphics for the windows.

We’ve wrapped all kinds of vehicles from Mini Coopers to utility trucks – we even did some lift trucks for a construction company. We do fleet wraps of anywhere from one to 30 or more vehicles. We wrap a lot of personal vehicles and boats as well. We also design, produce and install boat wraps for Marine Max in both their Naples and Fort Myers locations.

How has COVID-19 affected your business? Are you starting to see a return to normal?

Robert came on as my business partner in November 2019, and at that point, he knew us for what he saw on paper. He didn’t know the literal storms that we’ve weathered. As the pandemic started, he worried that our business would die. I had more confidence – we’d already made it through the hurricane and a full two-week closure. We had zero business then, but people came back on the schedule when the lights came on.

When the pandemic started, I told Robert that we’d see our wrap business slow down, but that we’d still be printing banners and magnets. Fortunately, we qualified for a PPP loan, and we were able to hit the ground running.

You’ve rejoined the hospital to help out during the pandemic. How is that going?

In March of 2020, I went back to work at the hospital on the weekends. My specialty, respiratory therapy, was especially needed due to COVID-19. I’ve maintained some shifts at the hospital throughout the year, and with help from everyone, we’ve been able to keep Inked Vinyl running full speed. One thing’s for sure – it’s been a crazy year.