Moving Forward with Advanced Sign LLC

Advanced Sign LLC | Meridian, Idaho

In today’s competitive marketplace, print service providers are constantly looking for ways to grow, increase their product offerings, and gain an edge over the rest of the pack. Some shop owners are finding that mergers are the best way to quickly add staff and production capability – thereby increasing their chances of staying in the game.

Advanced Sign LLC was formed in early 2020, when national provider Woodland Manufacturing, in Meridian, Idaho, acquired Advanced Sign & Design, a company with deep roots in the Boise community. The new firm is building off the strengths of both companies.

We spoke with Casey Space, VP of Marketing and Craig Miller, Business Development Manager at Meridian-based Advanced Sign, about the strategy behind the merger and how they are adapting to the new normal of life with COVID-19.

Please tell me about yourselves – what are your backgrounds?

Craig: My dad started a sign business in Boise, Idaho in the 1980s, when the industry was transitioning away from hand-painted signs to a franchised sign shop format. That evolved into additional shops in Phoenix, Arizona. My early experience in the industry was as an installer primarily focused on maintaining our commercial real estate clientele in Phoenix. I came home to run our family’s Signs Now shop in Boise for a few years which eventually led to its sale. I then moved back to Phoenix where we had evolved into a larger shop offering a full spectrum of projects. In time I decided to leave the business to pursue other endeavors until I was recruited by Advanced Sign. I haven’t taken on the role of designer but have managed most other facets of a traditional sign business, including administrative requirements.

Casey: I started at Woodland Manufacturing 13 years ago in customer service. When Google changed their algorithm to preference-rich, engaging content, Woodland took advantage of my English degree and asked me to write product descriptions and text for the website. One thing led to another, and now I’m VP of Marketing.

What made these two companies a natural fit?

Casey: Woodland Manufacturing had a strong online business across the nation. We kept a low profile locally because we had also been supplying products to local sign companies. We really wanted to be more a part of our community. We heard that Advanced Sign & Design might be looking for a buyer.

“Roland DG inkjets produce durable, high quality prints, and their color management software with the Pantone color library ties things together for us.”

Craig: Advanced Sign & Design was a traditional sign shop with a long history and deep roots in Boise, but almost no online presence. Merging with Woodland Manufacturing made a lot of sense – they are a much larger operation and could bring in that e-commerce know-how along with their amazing production capability and distribution channels. In addition, the owner felt the timing of selling the business afforded her a positive opportunity to retire from a long and successful career.

You just finished the merger, and then COVID-19 hit. How have things been going for you?

Casey: We entered the shutdown in an already vulnerable position because January and February are traditionally slower months for us. The mid-March slowdown made things even more challenging. Fortunately, Advanced is well connected in the community. With the increased production capacity from our merger, we could get a lot of product to businesses quickly. We started manufacturing hygiene shields right at the beginning. Our wooden sign business slowed down initially, but it’s starting to pick up again.

Craig: Just to add to that, a lot of our local clients are government agencies, utility companies and construction companies, all of which remained open. We are able to use curbside pick-up for our production and social distancing in the shop. We produce all the signage companies need to continue operating in the new environment.

Please tell me about your facility and production floor – are you under one roof yet?

Casey: There are still two facilities. Our main location has about 22,000 square feet and is in Meridian, about 15 miles outside of Boise. Advanced is a 12,000 square-foot shop, located in Boise. Right now, we don’t have room to move everyone in – with 70 staff members we’ll need some more space.

Our production floor includes digital printers, CNC machines, a water jet, a paint booth, and a powder coat oven. We can do almost anything. Our focus remains on quality and turnaround time. We can turn flat signs in three to five days, and finished, assembled signs in two weeks.

Craig: For our wide-format work, we use Roland DG printers in both facilities. Roland DG inkjets produce durable, high quality prints, and their color management software with the Pantone color library ties things together for us.

What are the most popular wide-format products you provide?

Craig: We are known locally for traffic products, in addition to many custom products not available in other shops. When we produce our reflective signage for applications tied to clients like Parks & Recreation, U.S. Forest Service, Bureau of Land Management, etc., we use our Roland DG printer/cutter to print the graphics on clear, then overlay them on sheeted reflective blanks.

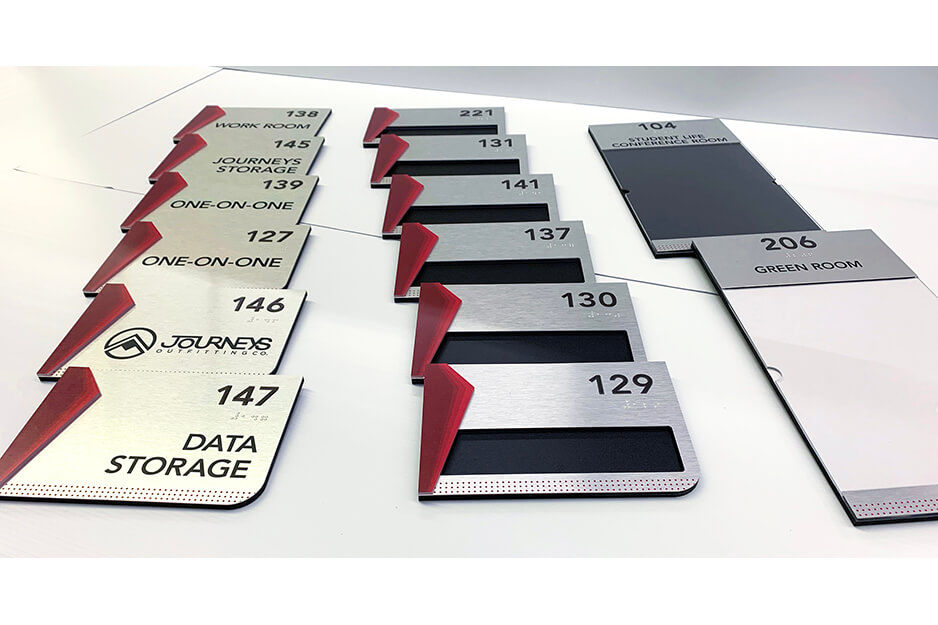

We purchased a Roland DG VersaUV LEJ-64FT UV flatbed printer because we had two projects laying at our doorstep for printing shorter sections of reflective material for large panels. These were large orders with big potential. We appreciated the quality of the flatbed prints, but what really sold us was that the LEJ also prints Braille. That was huge. Prior to that, we had been subbing out our ADA signage, so being able to control the variables in our production equation and the quality of our output was really important to us.

Over the past few years, we’ve really worked to start shifting the needle and expand beyond printing banners and traffic signs to doing wall murals, vehicle graphics and wraps, and wayfinding and event signage.

Casey: Woodland has an LEJ-640 hybrid/flatbed printer that we’ve used to print onto substrates like aluminum composite panel and acrylic signs. We chose it because of the quality of the prints, and because of the ease of use and reliability of the equipment. We’ve been really pleased with the durability of the prints as well.

What industries do you serve, and where are the majority of your clients located? Is this changing with the new organization?

Craig: We are fortunate to have the municipal contracts. That has always opened doors for us. Our Treasure Valley has grown so much, it’s not even recognizable – being tied into those types of entities helps people see our work. About 95 percent of our current clients are in the local area, which is of course evolving with the merger.

We serve everything from mom-and-pop shops to national corporations. Micron Inc. is based in Boise and we had an opportunity to work with their brand group to develop projects that went overseas as well as to trade shows in the World Trade Center in New York. With Micron, we were able to do all the environmental displays throughout their locations for their rebranded interior. We’ve also done ground-up signage work for IGI Resources and other nationally known companies.

As we started to move toward a wider variety of projects, more people are coming to us. We’re ready to help them.

What do you see as the future for your combined company?

Craig: As a smaller sign shop, we couldn’t control the elements we faced. We didn’t have the equipment or personnel. Now we feel like that world is open to us. We definitely saw it as opportunity for us to grow.

This industry is propelled by technology –if you don’t evolve or adapt, you’re just another little shop on the corner. The merger with Woodland has us well equipped to ask, “What can we do that’s going to make our clients’ business better?”

Casey: Advanced Sign has such a longstanding reputation in this valley and great name recognition. Boise is growing exponentially, but there’s still a community here. The opportunities that they are bringing to the table makes the future look really bright.

We like to say that we make quality signage so our clients can focus on what they do best.