Creating Opportunities with the Roland DG VersaUV

Lava Partners | Irvine, CA

Even in the current economy, Dean Passaglia sees opportunities. “There is always a need for packaging,” said Passaglia, creative director at Lava Partners in Irvine, California. “Our goal is to provide our clients with innovative packaging products that are developed within their budget.”

Lava Partners began in the late ‘90s as Lava Products, a packaging firm. Soon after, Lava Graphics was added, with design, pre-press and plate making abilities that functioned as a service bureau. As time went on, Lava Products developed Lava Marketing Group, and later added Lava Packaging, Lava Fulfillment and Lava Medical. “The umbrella name Lava Partners solved our identity crisis and the ‘how do we answer the phone’ dilemma,” said Passaglia.

These days, Lava Partners functions as an integrated marketing, design, printing and packaging solutions company that offers a broad range of services to clients throughout the retail and club store spectrum. With design services as well as pre-press production facilities, they are a full-service provider. In addition, Lava Partners has an in-house photography studio, which allows them to capture product images using high-resolution 24megPix D3x cameras and pro-flash lighting equipment and incorporate these high quality images into their designs.

To help Lava Partners efficiently manufacture realistic prototypes and short production runs, they purchased a Roland DG VersaUV series printer. “I had owned a Roland DG before and knew the quality Roland DG offers,” said Passaglia. “We bought the VersaUV with very high hopes, and so far, we haven’t found anything it can’t do for us.”

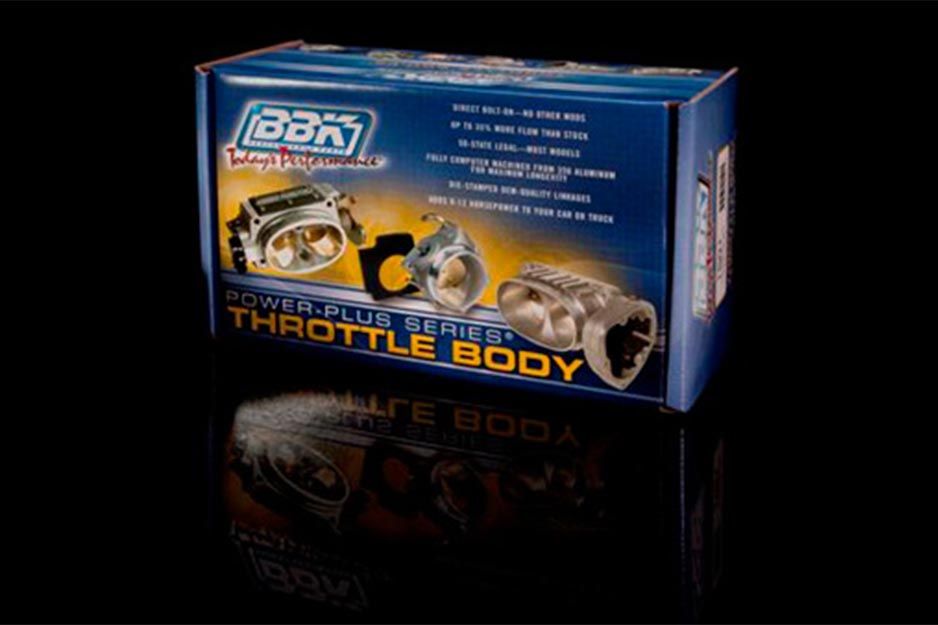

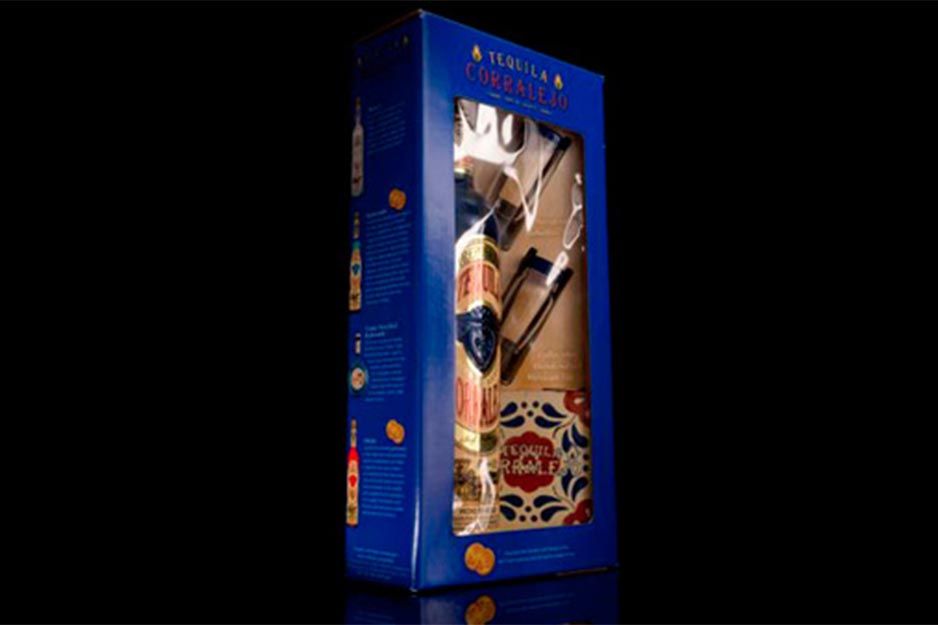

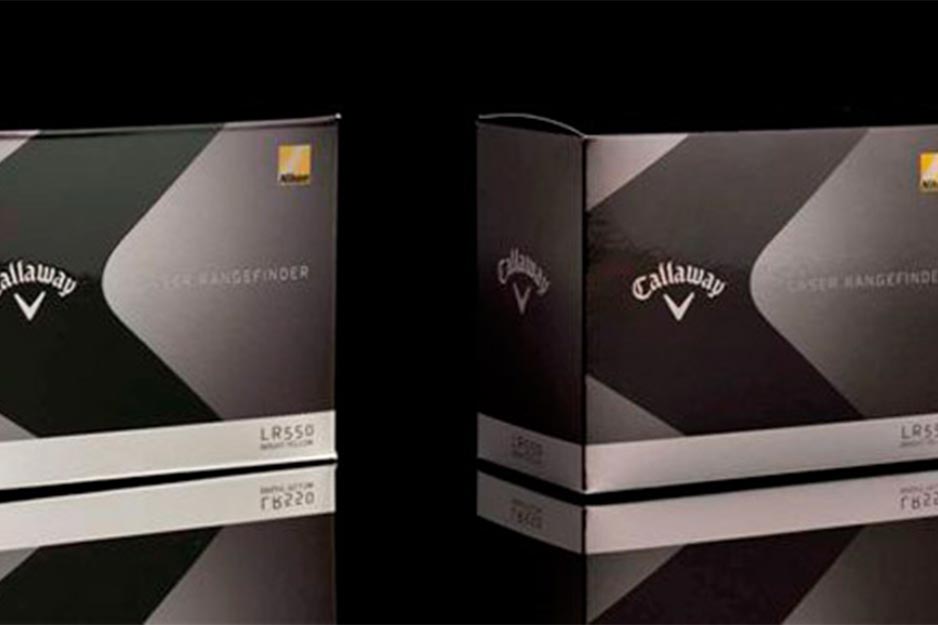

“Presenting a full-color mockup is so much better than asking clients to imagine your designs on a white box,” said Passaglia. “We design our packaging to impress and inspire our clients, and presenting a realistic prototype gives us a competitive edge.”

Lava Partners works closely with client companies or their ad agencies to develop packaging designs, and has found that a realistic prototype is the key to client presentations. “Presenting a full-color mock-up is so much better than asking clients to imagine your designs on a white box,” said Passaglia. “We design our packaging to impress and inspire our clients, and presenting a realistic prototype gives us a competitive edge.”

The VersaUV provides Lava Partners with a cost-effective way to generate its prototypes. “Over the years, we’ve hand-cut samples and used our large format printers for lithography and lamination,” said Passaglia. “The VersaUV lets us do all this on one machine, plus we can show spot UV treatments.”

Passaglia also values the variety of finishes and textures they can generate on the Roland DG UV printer. “We use a high gloss finish quite a lot,” said Passaglia. “With the white and clear coating together with CMYK, we have a lot of options for color, coatings and texture.” Lava Partners often creates an embossed look or simulates other textures to make their package graphics even more appealing. When they are satisfied with the look of the printed exterior, they use the printer's contour cut feature to score and die cut the material, and then they assemble the prototype.

In today’s highly competitive market, Lava Partners also values the VersaUV’s ability to handle a wide variety of substrates. “The range of materials we can use, from 18 point chip to labeling media, gives us a lot of flexibility in designing our packaging,” said Passaglia. “The machine prints and cuts just about anything.”

Lava Partners also uses the VersaUV for short run and specialty orders. Recently, one of their vendor partners asked Passaglia to design cover up labels for an in-store POP display. “We tried all kinds of media, but the lettering below the label would show through,” said Passaglia. They eventually had success with blackout material run on the VersaUV and contour cut to form labels. This process saved time and money, since there was no die cut set up involved. “It was the perfect solution,” said Passaglia. “In addition to cost savings, we win on customer service. We can do the short runs our clients need, and run them on whatever materials they need them run on.”

“The Roland DG VersaUV helps us provide a “wow factor” that gets customers excited about our designs,” said Passaglia.