Roland DG Technology Revolutionizes Hollow Jewelry Model Making

Brahim's Jewelry | Burlington, Massachusetts

Brahim Henniche of Brahim’s Jewelry in Burlington, Massachusetts, began using the Roland DG JWX-30 jewelry model maker in 2005. Since that time, Brahim has created hollow jewelry pieces in a fraction of the time it would take him to do so using traditional fabrication techniques.

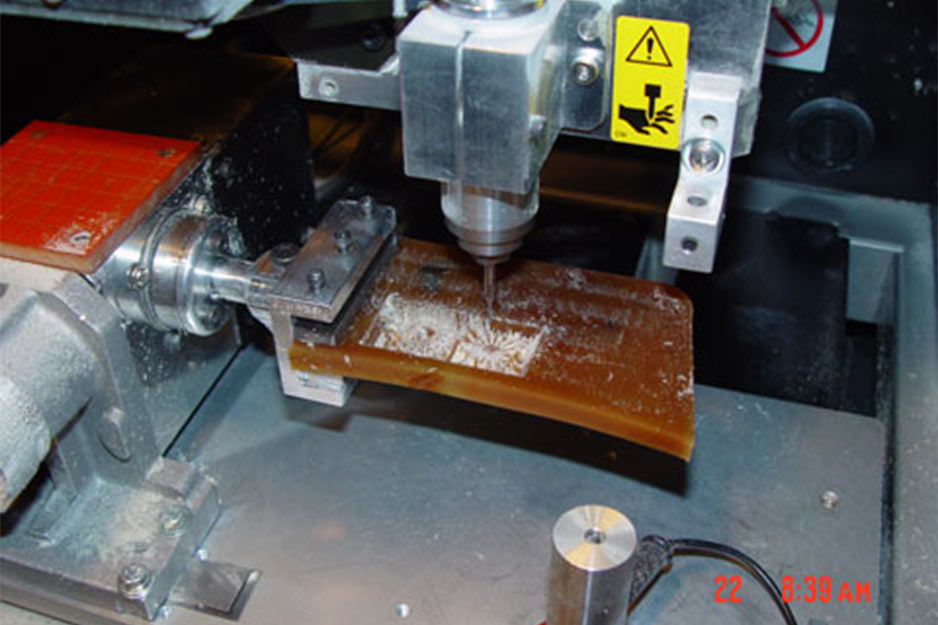

For this hollow flower ring, Henniche estimates that it would have taken him about 12 hours to hand fabricate the piece (not including setting and finishing). Using CAD/CAM, it took him only four hours: one hour to design the ring in CAD, two hours to mill the ring, and one hour to cast and solder the pieces together. In addition to making the process more efficient, the JWX-30 enabled Henniche to control the weight of a piece by segmenting it and hollowing it out.

“This enables me to create fine, delicate jewelry without the heaviness and resulting expense in metals,” said Brahim. “I chose to mill this ring in three pieces to control the weight of it but also because it milled faster this way while providing enhanced attention to detail, especially to the interior pattern of the top of the ring.”

“This enables me to create fine, delicate jewelry without the heaviness and resulting expense in metals.”

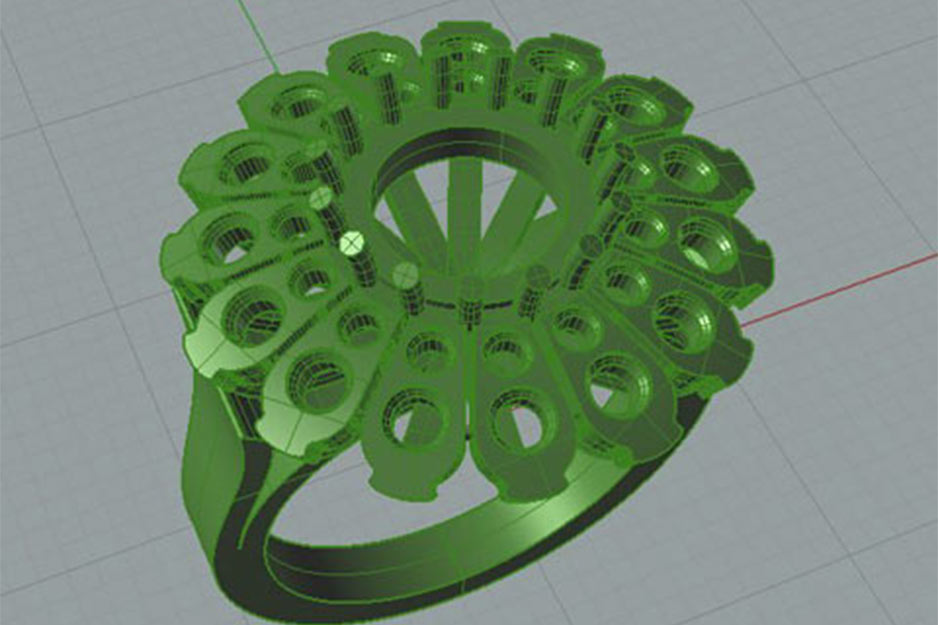

The white flower ring has a two carat round brilliant diamond in the center surrounded by fifteen petals, each holding two additional diamonds. Brahim designed the ring in CAD and produced the model using Roland DG’s JWX-10 mill using the following four steps:

- Brahim started this 14k white gold ring as he does all other designs, with a hand-drawn sketch. The customer wanted a diamond ring that resembled a flower.

- Once the sketch was approved, Brahim designed the piece using CAD softrware.

- Since the customer wanted the piece to be hollow, Brahim decided to mill it in three parts: the top, the gallery, and the shank. Milling of all three parts took about two hours.

- The parts were cast in gold and soldered together. Stone setting and polishing followed.