Custom Robotics Made Easy: An Interview with Robotics Hobbyist Michal Zalewski

Michal Zalewski

Michal Zalewski is a multitalented guy-a successful software engineer by day, and robotics hobbyist in the evening and on weekends. Many of his hobby creations have been spotlighted in the trade press. He also shares his projects with other hobbyists through his blog and website: lcamtuf.coredump.cx I recently asked him how he manages to accomplish so much in his off-work hours.

GM: Were robotics always an interest of yours?

MZ: I have had an interest in electronics, robotics, and just "making things," for as long as I remember. I never pursued this as a career choice - but I am fortunate enough to have an exciting job in software engineering that gives me both the freedom and the means to pursue this long-term passion.

I can't pinpoint it exactly, but there is something uniquely rewarding about creating complex, physical objects from scratch, sharing your knowledge and work with others... and with time, perhaps helping advance your field of expertise.

“The Roland DG MDX-15 milling machine was inexpensive and had all the right features.”

GM: What tools have proven helpful to you as you pursued your hobby?

MZ: I started thinking more seriously about robotics about six years ago, and quickly realized that the most significant limitation is the need to rely on very expensive pre-made or made-to-order structural components needed in moving assemblies, custom gearwheels, and so forth. Waiting a week and paying $50-$100 for a small part is simply impractical.

I investigated a number of options for manufacturing functional components quickly and cheaply - and eventually decided that precision CNC machining is the best option for my needs; but because the available documentation on the relevant CNC processes was very limited, I preferred not to make a substantial investment up front.

The Roland DG MDX-15 milling machine was inexpensive and had all the right features - especially with the bundled Modela Player software, which processes 3D CAD files for output on the MDX mill. It compared very favorably to other, typically bare-bones, products in that price range

GM: What features led you to upgrade your SRP<>

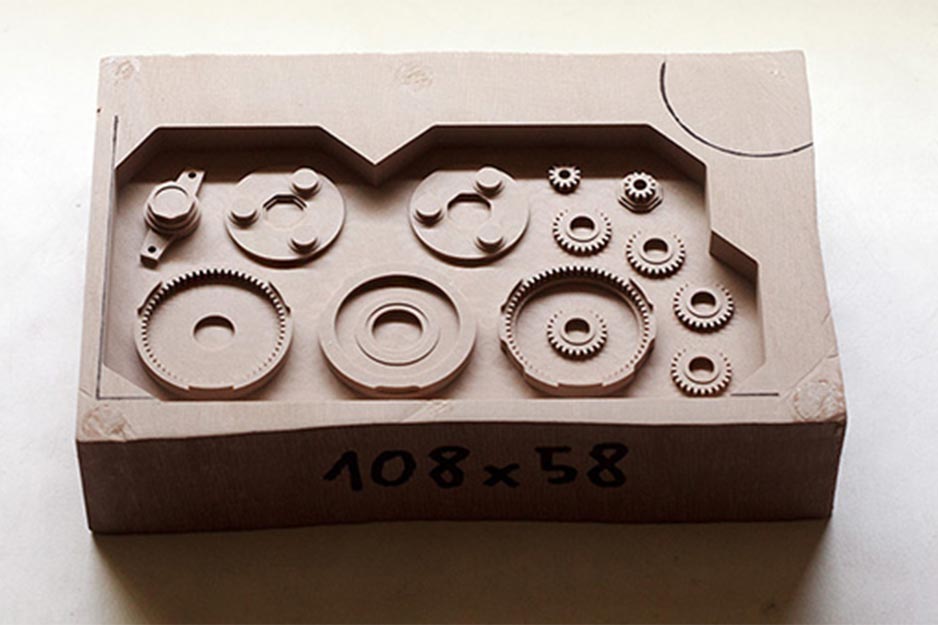

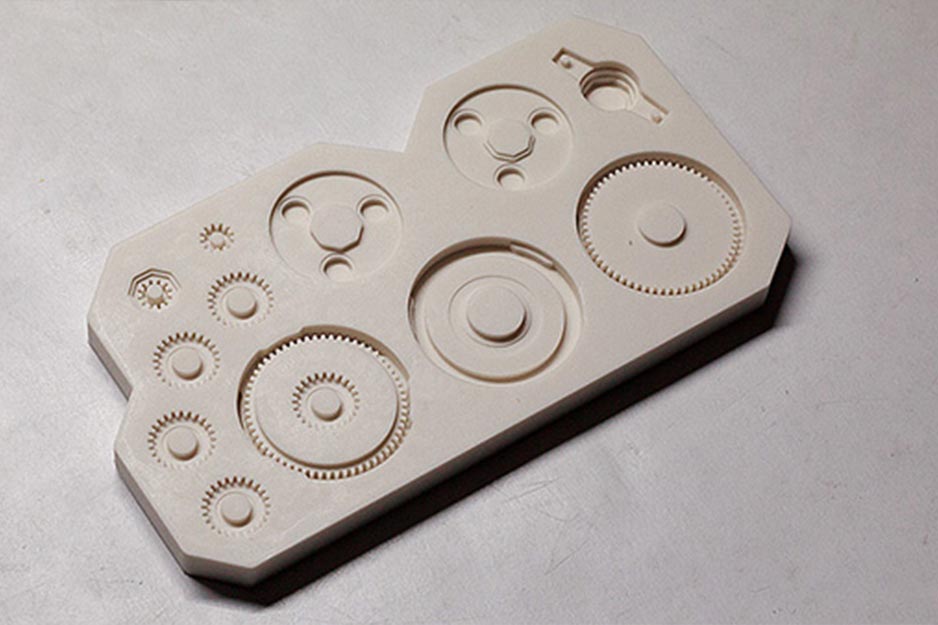

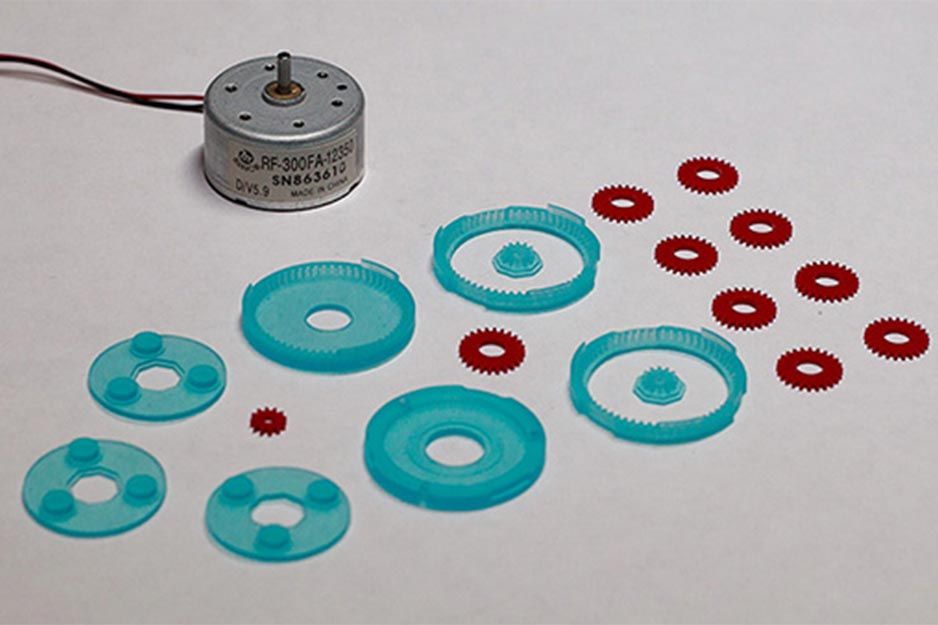

MZ: After some trial-and-error with MDX-15, I discovered the optimal process for my manufacturing needs: quickly machining positive master molds in RenShape prototyping boards, making flexible negative molds in 60-80 Shore A silicones, and casting final parts from high-strength, low-cost engineering plastics. Although this approach may seem unnecessarily complicated at first, is very cost- and time-efficient, the materials are highly predictable and you eliminate many of the stock material sizing and holding woes. Additionally, the parts can be quickly duplicated later on:

http://www.flickr.com/photos/candy-bottoms/sets/72157625850569320/detail/

At that point, I had confidence that I could benefit from the faster machining speeds and greater movement range afforded by Roland DG's larger MDX-540 benchtop CNC mill. The long-term returns of using the MDX-540 on part manufacturing costs, even in hobbyist uses - and simply the ability to experiment with designs at a whim - justified the upgrade for me.

GM: How does the MDX-540 perform for you in terms of its accuracy?

The MDX-540 yields a dimensional accuracy 0.0002" or better in my uses:

http://www.flickr.com/photos/candy-bottoms/4498562907/

...and enables me to machine features as thin as 0.0015". That is unmatched by any other technology within that price range.

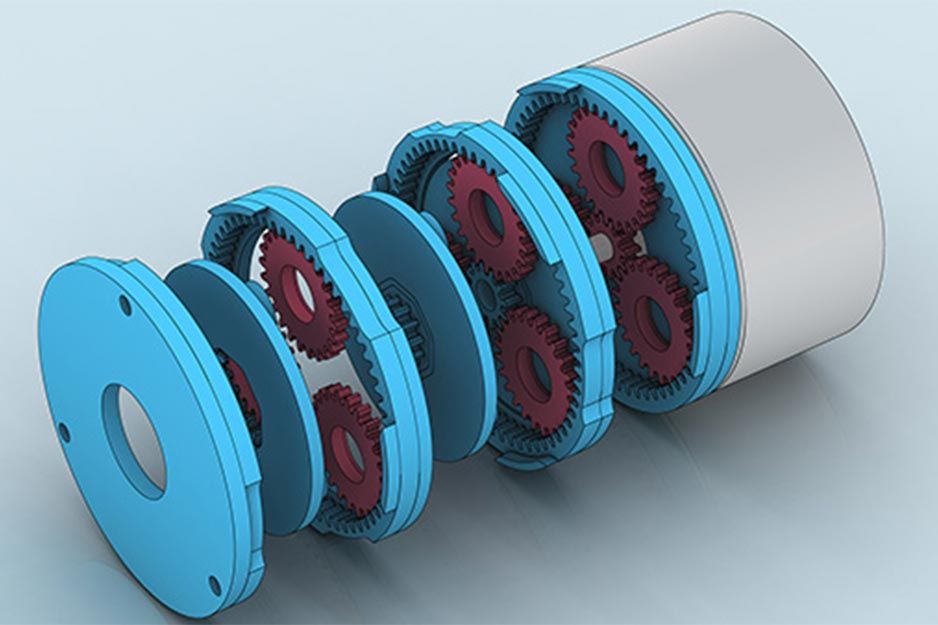

Perhaps the two most demanding applications I am routinely dealing with are custom-machined subminiature gearwheels and snap-fit sleeve bearings. In these applications, dimensional accuracy must stay within 0.0004" or so; the MDX-540's accuracy is several times better in my experience.

GM: Would you please describe a typical project?

MZ: Since I'm pursuing robotics as a hobby, every project is unique - I try to experiment with new ideas and push my own limits when it comes to electronic and mechanical design. I have experimented with everything from miniature quadruped robots:

http://lcamtuf.coredump.cx/robot/show_image.cgi/pmma_microbot.jpg

...to a variety of wheeled designs with various conventional and unconventional steering systems:

http://lcamtuf.coredump.cx/robot/show_image.cgi/tinybot_render2.jpg

...but I frequently also tinker with fun ideas that do not have much to do with practical robotics - for example, a machine whose sole purpose is to turn itself off:

http://lcamtuf.coredump.cx/ultimate/

...or a completely impractical wall display mirroring DHS threat levels:

http://lcamtuf.coredump.cx/word/

...or a 3D laser scanner for photographic uses:

http://lcamtuf.coredump.cx/25d/

I typically design my projects in Rhino CAD software, although I have used other programs for some projects.

While CNC systems seem to be far more predictable and accurate than all the sanely-priced additive prototyping solutions, there were several things I still needed to figure out to get perfect results - from material selection to toolpath strategies - and for plastics, I had to learn it the hard way. To help others, I put together a ridiculously detailed guide to the process.

GM: What features of your SRP system are most helpful to you?

MZ: Precision and resolution are definitely the two most significant selling points for me; high cutting speeds and a very generous movement range are next. I have looked at the performance of some other CNC systems on the market and the MDX-540 compares very favorably on all these counts.

The MDX's handy panel (hand-held control panel) is a minor feature in the grand scheme of things, but also a very helpful one: it's very useful to be able to be next to the working area when configuring origins, measuring tool height, adjusting cutting speed, or verifying process parameters. I would miss this convenience if forced to switch to a different milling machine.

Additionally, the systems have been very reliable. I have had absolutely no mechanical or electrical problems in three years of service with the MDX-540- the machine is still performing like new. I also had no problems with the MDX-15 I owned previously.

GM: What are projects are you working on lately?

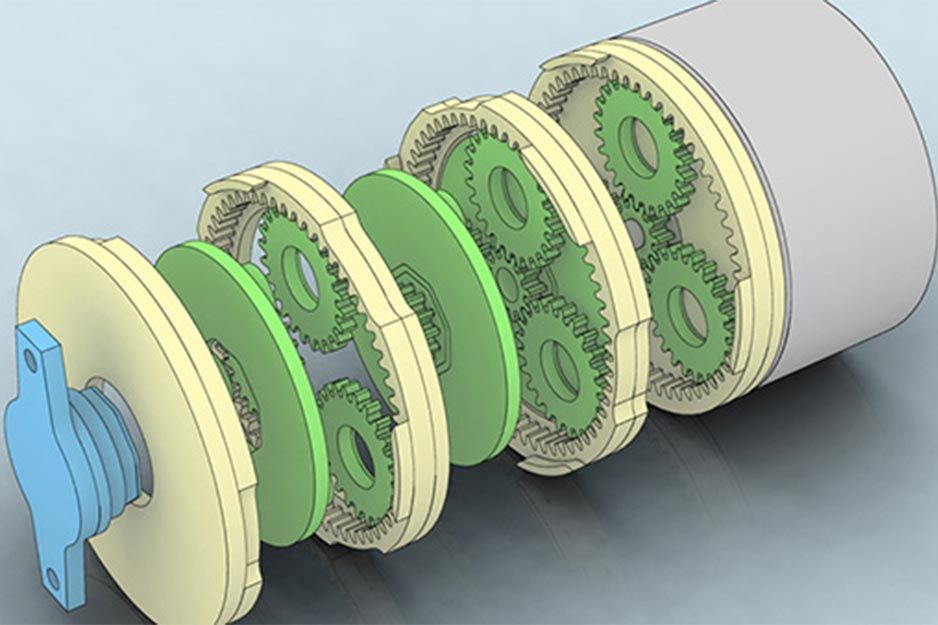

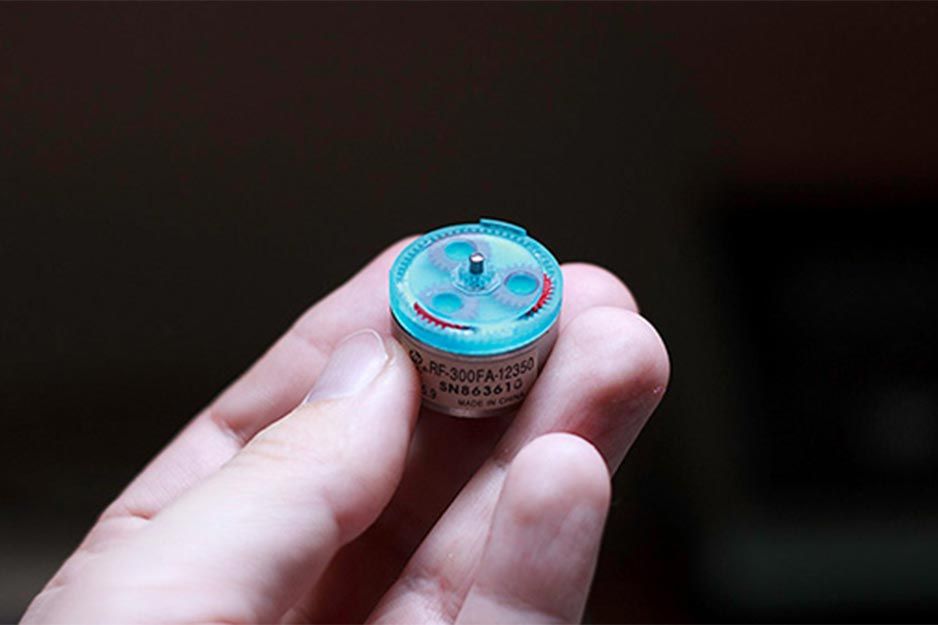

MZ: I try to do something new with every project, and with this comes a unique set of challenges; for example, my current project started with a custom-made planetary gearbox for each of the motors; every gear in that mechanism is barely 0.035" thick, and has 0.015" teeth that need to mesh perfectly at that scale:

http://lcamtuf.coredump.cx/robot/show_image.cgi/omnibot-02-3dcad.jpg

GM: Overall, what has the impact been of SRP technology on your project work?

In terms of the impact, I simply think that most of the designs I worked on in the past few years would be completely impossible without this tool: even though custom parts can be mail-ordered today, that approach simply does not allow for any trial-and-error or continuous refinement of your projects.