Roland DG Initiates Joint Research on Laser Fabrication Technology with GPI

Hamamatsu, Japan, June 28, 2016 – Roland DG Corporation, a leading manufacturer of desktop fabrication devices worldwide, has announced the start of a joint research relationship with GPI, the Graduate School for the Creation of New Photonics Industries located in Hamamatsu, Japan. The collaboration will study the application of femtosecond laser technology to the fields of 3D fabrication and healthcare where Roland DG is currently exploring various options to expand its business.

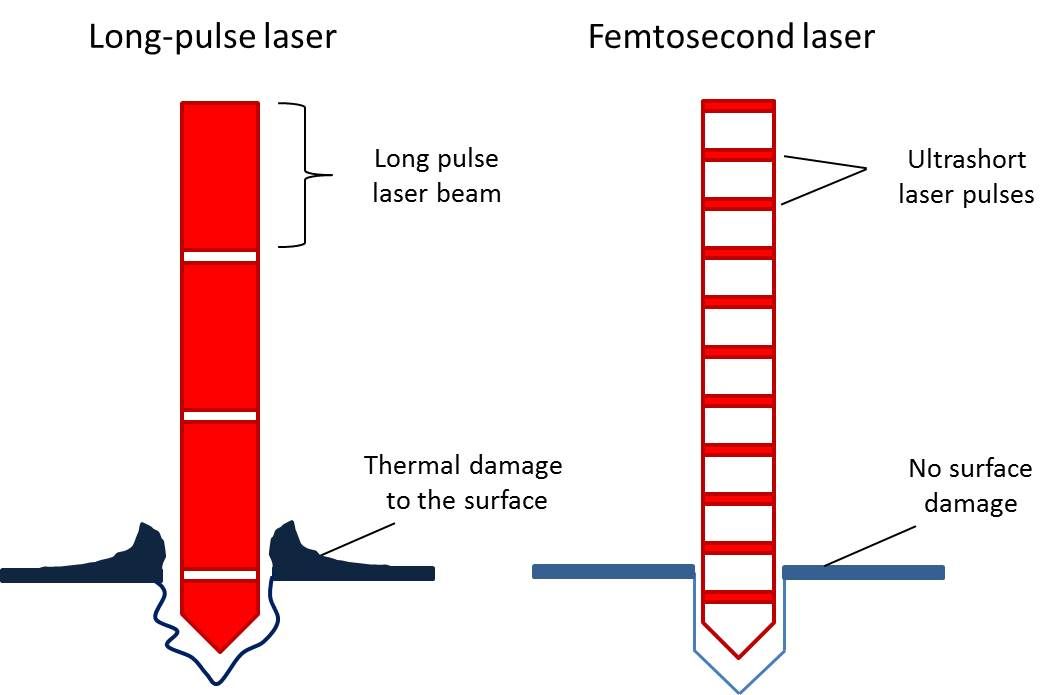

A femtosecond laser is an ultrashort pulse of intense light which is concentrated at a femtosecond (one quadrillionth of a second). Peak power is generated by compressing and oscillating the pulse length of a laser to a few femtoseconds. Melting or thermal damage to the irradiated area and its surroundings are reduced due to the laser’s ablation effect*, making femtosecond lasers highly effective for precision fabrication with extremely hard materials, or for operations such as Lasik eye surgery that require extreme accuracy. Currently, practical applications of the femtosecond laser have expanded into fabrication with industrial metals and carbon fibers, keratorefractive surgery and cataract treatment, and research and development in biotechnology. Challenges remain, however, including downsizing and cost reduction of the oscillator, which is required to create a femtosecond laser, and conducting further research on how materials change during fabrication.

Hisashi Bito, Executive Officer and division vice president of Easy Shape business development at Roland DG, said, “Through this joint research, our company is aiming to explore the possibility of applying femtosecond laser technology to our 3D digital fabrication and healthcare areas with the objective of producing the first desk-top femtosecond laser fabrication machine.”

Yoshihiro Takiguchi, Vice-President of GPI and professor of optical information and systems, added, “At GPI, we are looking forward to investigating new industrial applications for laser processing with the goal of creating new industries. The state of the art ultrashort pulse laser we are using was acquired with the financial support of the Japanese government and has the ability to instantly ionize matter. By combining the ultrashort pulse laser to the Roland DG’s 3D digital fabrication tools, we can enhance our knowledge of how materials change during fabrication, and how we can apply the latest laser technology to a variety of industries.”

*A phenomenon whereby the fabricated object reaches a plasma state by irradiating a high strength laser beam to its surface. Since this method does not create any bumps or distortion around the fabricated area and the effect of the heat is very limited, it is possible to achieve a high quality finish.

About the Graduate School for the Creation of New Photonics Industries (GPI)

Founded in 2006 with the assistance of various Japanese companies including Hamamatsu Photonics and Toyota, GPI provides a Ph.D. program for students with an entrepreneurial spirit to create new photonics industries. Entrepreneurs, scientists and engineers, and presidents and top managers of small- to mid-sized companies come to GPI to develop their business plans with hands-on support by the professors with management and technical expertise.

For more information about GPI, please visit: http://www.gpi.ac.jp/en/index.html

About Roland DG Corporation

Roland DG Corporation is a leading manufacturer of products designed to help professionals and hobbyists transform their imagination into reality, including SOLJET, TrueVIS, VersaCAMM, VersaUV and Texart series large-format inkjet devices, MDX milling and EGX engraving machines, CAMM-1 and STIKA vinyl cutters and MPX photo impact printers. In 2010, the company entered the healthcare market with Easy Shape DWX milling machines designed specifically for creating high-quality dental prosthetics. Roland DG also recently introduced the monoFab series of desktop 3D printers and milling machines for rapid prototyping and manufacturing. The company uses its proprietary cell production technology to manufacture products that are distributed worldwide.

For more information, please visit www.rolanddg.com.