Teaching Students About State of the Art Digital Printing Technology

RIT | Rochester, New York

The Rochester Institute of Technology (RIT)'s School of Print Media is known for leveraging its state-of-the-art facilities to prepare graduates for careers in printing and publishing. The recent inclusion of Roland DG's VersaUV 30-inch UV inkjet printer/cutter has helped to fill an important need in their curriculum and research.

"The VersaUV has generated a lot of excitement among the staff and students. It raises the bar with multiple colors and surface effects," said Erich Lehman. "The students have used it to turn out some really innovative work."

Lehman is premedia facilities coordinator and adjunct faculty at RIT's School of Print Media, where he and his students have the opportunity to test out the latest in printing technology from a variety of manufacturers. In the facilities Lehman oversees, students in courses such as Digital Asset Management, Packaging Design, Color Management, and Digital Foundations use a full range of printing equipment to output their projects, creating over 15,000 job tickets each year.

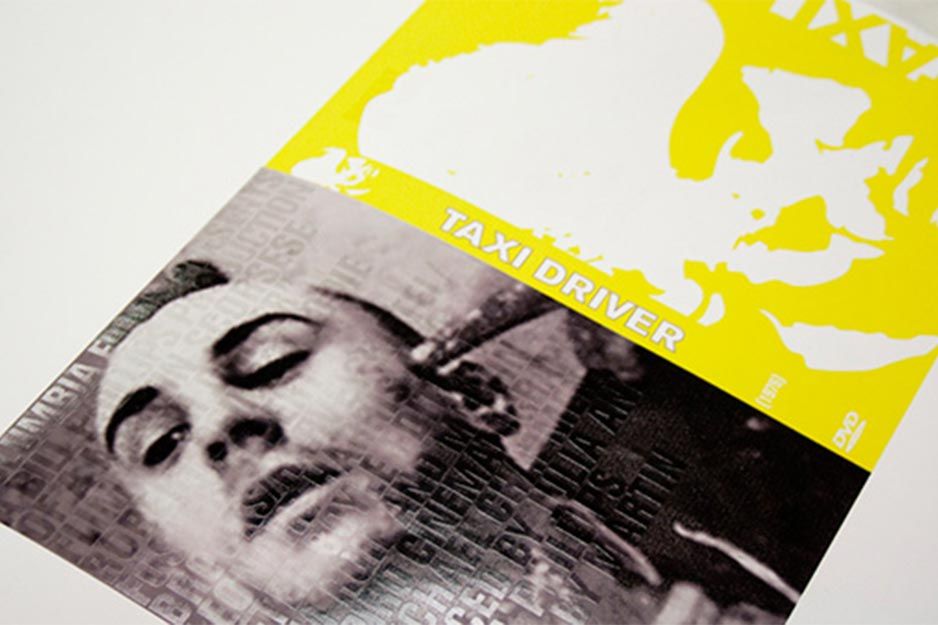

Students use the VersaUV to print stickers, banners, marketing materials and packaging prototypes, among other projects. They employ the automated cutting feature for decals and stickers, and use the Print/Cut and creasing functions to create folding carton prototypes of any shape. "Being able to cut automatically is huge," said Lehman. "The students save time and learn to plan for production."

“With our diverse base of users, we really need equipment that is both robust and easy to use and maintain," said Lehman. "The Roland DGs have always delivered for us.”

Students often employ the VersaUV's white and clear coats on their designs, creating gloss and texture. "The clear coat has been incredibly popular," said Lehman. Students also enjoy using the gloss effects to add texture and interest to their projects. "They are pretty stoked about the machine's capabilities," said Lehman.

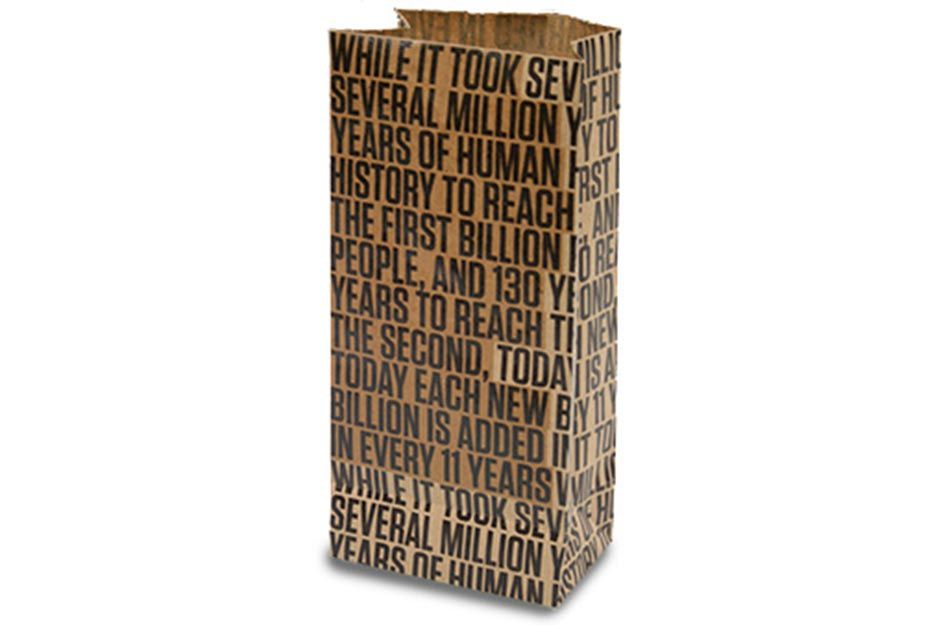

With several projects due each quarter, students have also been experimenting with the wide variety of substrates that can be run on the LEC. "The VersaUV prints on almost anything you can squeeze through it," said Lehman. "Our students have run their projects on everything from craft paper to rice paper to board." As students get more familiar with the machine, Lehman anticipates more projects being run on a range of polyethylene materials as well as other, more innovative substrates.

“With our diverse base of users, we really need equipment that is both robust and easy to use and maintain.”

Lately, students have been using Roland DG's VersaUV to help them turn out innovative packaging designs. RIT students recently won top honors in the American Packaging Corp./Kraft Product Design Challenge at RIT. In the four-week challenge, students from the industrial and graphic design departments worked with packaging science students to create new packaging for familiar brands, including Planters Peanuts, Wheat Thins, Oreos and Nutter Butters. The teams' formal presentations were judged by representatives from the sponsoring companies.

Professor Alex Lobos of the School of Industrial Design noted that having the VersaUV allowed the students to produce actual prototypes rather than appearance models. 'This is a critical difference for the students as well as for the judges. The packages were created as designed, with nothing lost in translation," said Lobos. He also credited the VersaUV with allowing the students to attain an additional level of understanding of the production process. "Students were able to have a much deeper discussion about design and material choices for this project since they were printing on the final production substrate," said Lobos.

Since digital printing is a relatively low cost printing process, Lehman's students can afford to take more design risks. "It's an incredible way to learn," said Lehman. "Digital printing is cost-effective, so the students don't have to worry as much about the expense when they try something and it doesn't work out." Lehman believes the training and experience his students get while printing their projects on the LEC will make them better designers and better managers. "Digital printing is a microcosm of all the other printing processes," said Lehman. "The critical thinking skills they develop here will help them throughout their careers."

"Printers like the VersaUV definitely represent an important facet of the industry's future," said Lehman. "It's really exciting to have the Roland DG technology available and to see what the students are able to do with it."