Closing the Gap Between Concept and Consumer

CSW | Ludlow, Massachusetts; Rochester, New York; Toledo, Ohio

Founded in 1937 and still thriving today, integrated packaging solutions provider CSW has evolved rapidly to keep up with the many changes in the packaging industry. Today CSW has approximately 150 employees in three locations: Ludlow, Massachusetts, Rochester, New York and Toledo, Ohio.

CSW serves clients such as P&G, Bose, and Nestl_ along with an impressive array of national and local firms, designing everything from folding cartons to pressure-sensitive and shrink wrap labels. As part of its ongoing transformation, CSW has positioned itself as an "asset bridge" between concept and consumer through its premedia spinoff, Bridge Premedia (www.bridgepremedia.com).

In 2010, CSW identified a need to quickly and economically produce physical prototypes. Their solution? The Roland DG VersaUV LEC 30" UV inkjet printer. "The VersaUV is just a better tool to further our ability to produce a physical prototype," said Marek Skrzynski, director of graphics, R&D at CSW. "We had been making our own mock-ups for a year with limited success and lots of aggravation. The VersaUV made most of our prototyping troubles go away."

Skrzynki noted that the use of physical prototypes is increasing as project turnaround times decrease. CSW's goal these days is to complete projects within two to three days. "The key is effective communication," said Skrzynski. "Physical mock-ups can resolve many design questions and a lot of technical issues very quickly."

“The moment of truth is when the package arrives and makes an impact," said Skrzynski. "We put so much effort into the process of getting that three to four seconds of attention in the aisle. It's essential to look at your package in a real application - it can't just be a flat simulation. You want your package to win among all those SKUs screaming for consumers' attention. Prototyping is a way to evaluate your strategy and make sure of that win. In the future, this kind of direct-substrate 3D proofing will be the norm for package design development.”

In addition to allowing for fast and accurate prototyping, the VersaUV helps CSW contain production costs. "Prototypes need to be visually effective and economically feasible," said Skrzynski. "In the past, our clients would order physical prototypes only once or twice a year due to the high production costs. Now prototypes are becoming an everyday tool in the development of a design."

Skrzynski also values the wide variety of substrates that the VersaUV can print on directly. He notes that being able to print on the actual material used in the final packaging not only makes the model more authentic, but saves additional costs for his client. "I don't want to spend more time and money preparing that substrate _ I want to print on it," said Skrzynski. "With the VersaUV, you name it, we run it. As long as I can fit it in the machine thickness-wise, it goes through."

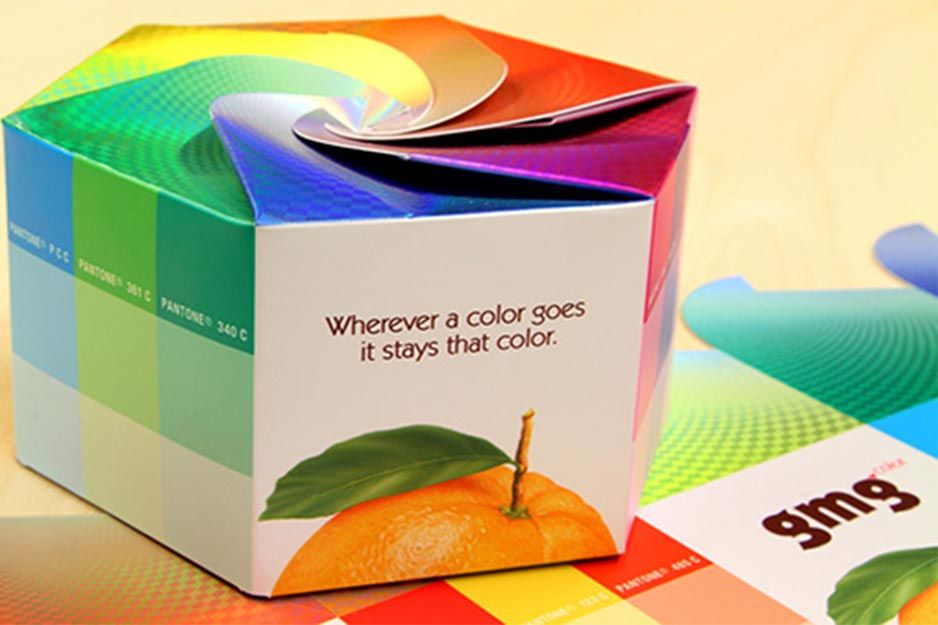

CSW uses prototypes as a visual confirmation of the design's intended result. "You can confirm that what looks nice, also looks correct," said Skrzynski. He noted that drawings and even 3D graphics do not always account for distortions created by folds or cavities. In addition, a physical prototype gives clients the experience of holding the package and judging how the substrates and coatings feel. "Packaging specifically is usually three dimensional and the substrate plays a huge role. The feel of a package is very important," said Skrzynski. "The sensations we receive from our sense of touch may either please us or put us off."

"In packaging, color is king," said Skrzynski. CSW uses Roland DG's VersaWorks RIP software in combination with a color management tool from GMG, which partnered with Roland DG to provide superior color management and proofing software. "GMG's color engine did magic for us. We need to be able to not only run on the exact substrate the client wants to use, but to predict exactly what the color will look like on the press and represent that on the prototype, " said Skrzynski.

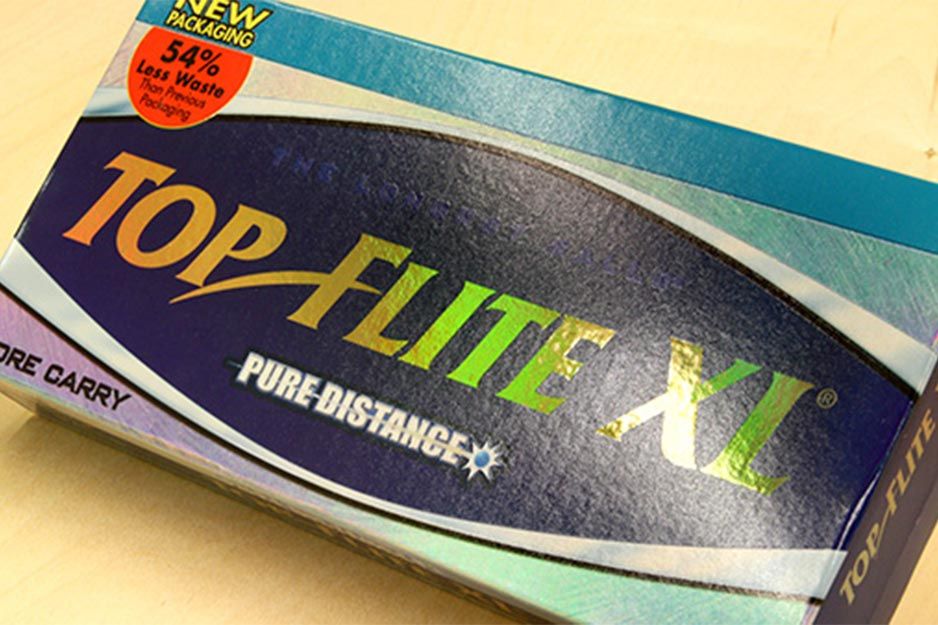

To guarantee superior results, CSW relies exclusively on Roland DG inks. "We did internal tests before we pulled the trigger on the purchase. The colors that were coming from the press and those we produced on the VersaUV were within industry acceptable range," said Skrzynski. "When we print our mock-ups, they are the most realistic prototypes money can buy. We always get correct color and proper ink opacity, which in case of printing on a transparent substrate is critical.

The ability to print white ink is also increasingly valuable in the marketplace. In the past, Skrzynski commented, they would use additional lamination to imitate white ink on the mock ups. "With the VersaUV, we can finally print white ink. More and more designers are using white as a design element, and we need to be able to show them what that looks like," said Skrzynski.