DMS Color Expands Packaging Offerings with UV Digital Print

DMS Color | Pelham, Alabama

DMS Color in Pelham, Alabama, describes itself as “a technology company with sophisticated printing capabilities.” That’s an understatement. With 75 employees, web-based asset management solutions, and equipment capable of producing almost any type of marketing collateral - from an annual report to embossed packaging - DMS Color is prepared to help its clients meet all the challenges of today’s marketplace.

We talked with CEO/CTO Matthew Greer to find out how Roland DG digital inkjet printers are helping DMS expand one of its fastest growing divisions - its packaging business – and the role this technology is playing in the development of his company’s first direct-to-consumer offering.

How did DMS Color get its start?

Matthew Greer: We launched as Digital Marketing Services in 2006, initially working out of a basement. When the business gained some traction, we moved to an incubator space. From there, we transitioned into one unit of a six-unit Butler building. Soon, we expanded to take up five of the six units, and from there we moved to our own facility. We were there for two years, and then moved to our current 55,000-square-foot facility. Now, we are looking to expand to 75,000 square feet by adding the facility next door.

Our major business divisions include DigiFlo, which is our web-based solutions division, Digilab, Design Studio, Large-Format Printing, Packaging, Promotional Items, Corporate Printing, Stickers and Labels, and Brewery Marketing.

Our clients include health services companies, breweries, retail stores, restaurants, athletic teams, industrial manufacturers, and companies from almost every industry you can think of. We are pleased to say we’ve been ranked in Printing Impressions’ Top 350 list as one of the largest printers in the US/Canada.

We currently have 75 employees with a wealth of experience. We have a showroom area and office space as well as production areas, and we meet with our clients by phone, online or in person.

How did you decide to invest in your first digital inkjet printer?

We purchased our first large-format inkjet – a Roland DG SOLJET printer/cutter – in response to our customers’ requests for “onesie- twosie” orders for banners, decals, car clings and posters. We find that having the print-and-cut capability increases our “stickiness” with clients by giving us the ability to say yes to more of what they need.

What led you to add digital UV print capability?

Initially, we simply wanted a printer capable of printing white and gray boxes for our Packaging division. We looked to Roland DG again because of its quality and durability. We purchased the Roland DG VersaUV LEC2-300 in early 2020 to print boxes and to produce tamper-resistant labels. From there, we’ve expanded our applications to include short-run labels, customer samples, and package prototyping.

What products are you producing on your UV printer?

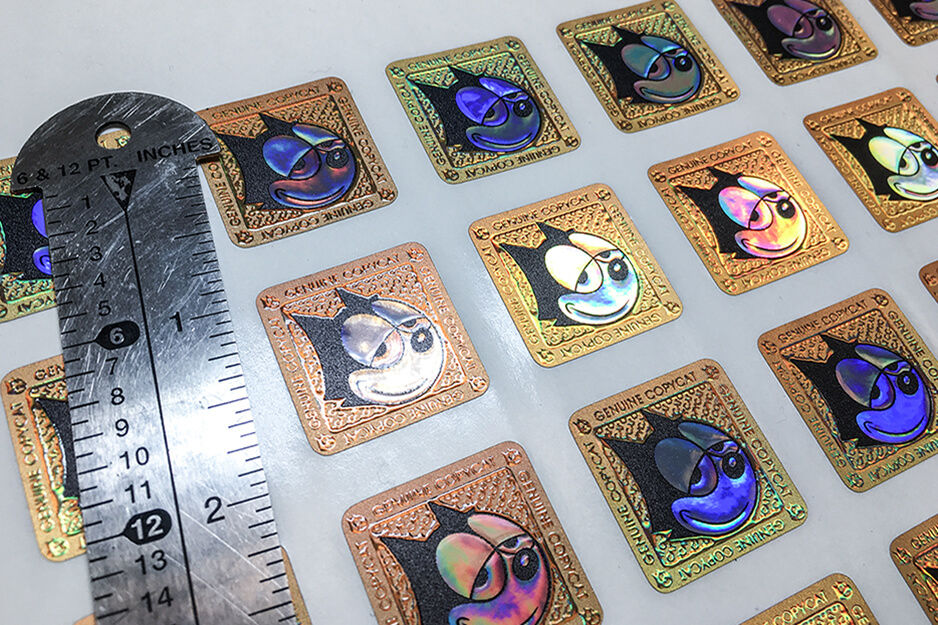

We produce labels for jar tops and sides, tube labels, can labels, security labels, as well as 12-ounce and 16-ounce aluminum can prototype labels. We run anywhere from 1-7,500 pieces, typically ranging from 0.5-inch circles to 5 by 10-inch decals. We also do one-offs for samples and prototypes.

We primarily print on Silver, White, and Holographic BOPP (biaxially-oriented polypropylene). We also print on cling material, hemp material, and white and clear vinyl.

Our Packaging division has grown rapidly over the past 18 months. The embossing feature on the LEC2 has been a real game changer. Clients love the embossing, especially over silver and holographic material.

How important is color management for your clients? Have you been able to color match across devices?

For us and for our clients, color management is critical. The Roland Color Library allows us to control the output and match spot colors with ease.

How has your business been affected by the pandemic?

When the pandemic shutdown occurred, our commercial segment and corporate print segment were hit pretty hard, and those areas haven’t fully recovered. We lifted things up a bit with PPE sales to the healthcare space.

There has been a lot we’ve had to pivot and deal with, including keeping jobs afloat, but we are starting to see some signs of improvement. Our Packaging division has really taken off in the last 18 months, and it continues to grow. Seeing improvement for our brewery and professional services clients would signal a broader recovery for us.

What lies ahead for DMS Color’s Packaging division?

We continue to see interest in the markets we serve for packaging and labeling products. Through one of our brands, Goldleafpackaging.com, we are launching an online storefront where consumers can directly purchase custom labels for various containers. We’ve been building online stores for the past 10 years, however those were for industrial and commercial customers. This is our first B-to-C online store.

We believe that the spot color and embellishment capability of the Roland DG LEC2 UV printer has really helped our Packaging division flourish. Our customers appreciate the extra touches that set their packaging apart from their competitors’.

We talked with CEO/CTO Matthew Greer to find out how Roland DG digital inkjet printers are helping DMS expand one of its fastest growing divisions - its packaging business – and the role this technology is playing in the development of his company’s first direct-to-consumer offering.

How did DMS Color get its start?

Matthew Greer: We launched as Digital Marketing Services in 2006, initially working out of a basement. When the business gained some traction, we moved to an incubator space. From there, we transitioned into one unit of a six-unit Butler building. Soon, we expanded to take up five of the six units, and from there we moved to our own facility. We were there for two years, and then moved to our current 55,000-square-foot facility. Now, we are looking to expand to 75,000 square feet by adding the facility next door.

“We believe that the spot color and embellishment capability of the Roland DG LEC2 UV printer has really helped our Packaging division flourish.’”

Please describe your business today.Our major business divisions include DigiFlo, which is our web-based solutions division, Digilab, Design Studio, Large-Format Printing, Packaging, Promotional Items, Corporate Printing, Stickers and Labels, and Brewery Marketing.

Our clients include health services companies, breweries, retail stores, restaurants, athletic teams, industrial manufacturers, and companies from almost every industry you can think of. We are pleased to say we’ve been ranked in Printing Impressions’ Top 350 list as one of the largest printers in the US/Canada.

We currently have 75 employees with a wealth of experience. We have a showroom area and office space as well as production areas, and we meet with our clients by phone, online or in person.

How did you decide to invest in your first digital inkjet printer?

We purchased our first large-format inkjet – a Roland DG SOLJET printer/cutter – in response to our customers’ requests for “onesie- twosie” orders for banners, decals, car clings and posters. We find that having the print-and-cut capability increases our “stickiness” with clients by giving us the ability to say yes to more of what they need.

What led you to add digital UV print capability?

Initially, we simply wanted a printer capable of printing white and gray boxes for our Packaging division. We looked to Roland DG again because of its quality and durability. We purchased the Roland DG VersaUV LEC2-300 in early 2020 to print boxes and to produce tamper-resistant labels. From there, we’ve expanded our applications to include short-run labels, customer samples, and package prototyping.

What products are you producing on your UV printer?

We produce labels for jar tops and sides, tube labels, can labels, security labels, as well as 12-ounce and 16-ounce aluminum can prototype labels. We run anywhere from 1-7,500 pieces, typically ranging from 0.5-inch circles to 5 by 10-inch decals. We also do one-offs for samples and prototypes.

We primarily print on Silver, White, and Holographic BOPP (biaxially-oriented polypropylene). We also print on cling material, hemp material, and white and clear vinyl.

Our Packaging division has grown rapidly over the past 18 months. The embossing feature on the LEC2 has been a real game changer. Clients love the embossing, especially over silver and holographic material.

How important is color management for your clients? Have you been able to color match across devices?

For us and for our clients, color management is critical. The Roland Color Library allows us to control the output and match spot colors with ease.

How has your business been affected by the pandemic?

When the pandemic shutdown occurred, our commercial segment and corporate print segment were hit pretty hard, and those areas haven’t fully recovered. We lifted things up a bit with PPE sales to the healthcare space.

There has been a lot we’ve had to pivot and deal with, including keeping jobs afloat, but we are starting to see some signs of improvement. Our Packaging division has really taken off in the last 18 months, and it continues to grow. Seeing improvement for our brewery and professional services clients would signal a broader recovery for us.

What lies ahead for DMS Color’s Packaging division?

We continue to see interest in the markets we serve for packaging and labeling products. Through one of our brands, Goldleafpackaging.com, we are launching an online storefront where consumers can directly purchase custom labels for various containers. We’ve been building online stores for the past 10 years, however those were for industrial and commercial customers. This is our first B-to-C online store.

We believe that the spot color and embellishment capability of the Roland DG LEC2 UV printer has really helped our Packaging division flourish. Our customers appreciate the extra touches that set their packaging apart from their competitors’.