World's Premier Consumer Health Company Chooses Roland DG for Fast and Functional Toothbrush Prototypes

Johnson & Johnson

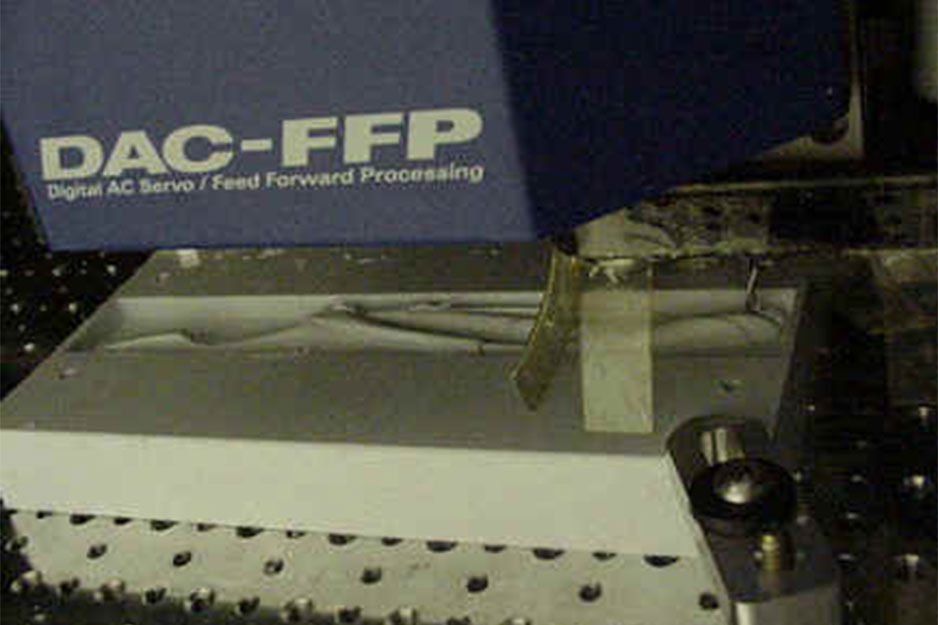

Thanks to Roland DG's bench top milling machines, Johnson & Johnson is able to bring toothbrushes to market faster, but reduce the development costs at the same time.

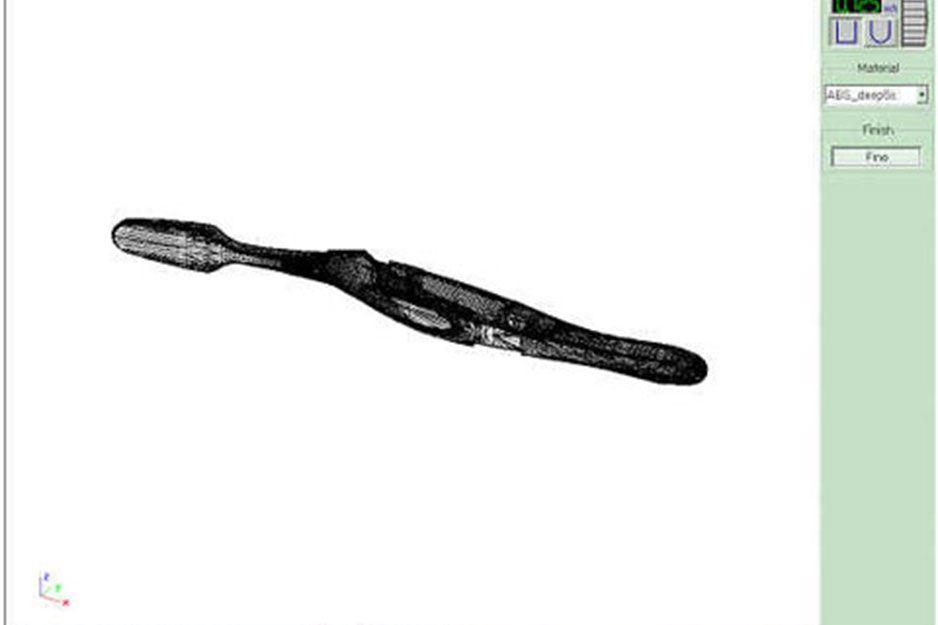

The ability to produce precision prototypes from the same material as the final product is the key. It lets Johnson & Johnson fully evaluate the product before going into production, allowing them to identify and work out potential design issues early on in the process. These prototypes actually work!

In vitro tests reveal everything from product wear and fatigue to fit and aesthetics. After that, focus groups and observed consumers actually use the prototypes. If a prototype fails at any point during testing, the design goes right back into the CAD software program for re-editing. In some cases, the product goes all the way back to the drawing board for the industrial designer to create a new model.

“Roland DG's bench top milling machines accept so many materials that we able to test for FDA consumer guidelines and evaluate them for usability before any production begins.”

“Roland DG’s bench top milling machines accept so many materials that we able to test for FDA consumer guidelines and evaluate them for usability before any production begins,” said Justin McDonough, Johnson & Johnson product designer. “It saves us so much time and money.”

Once production begins, correcting problems is much more cumbersome and expensive.

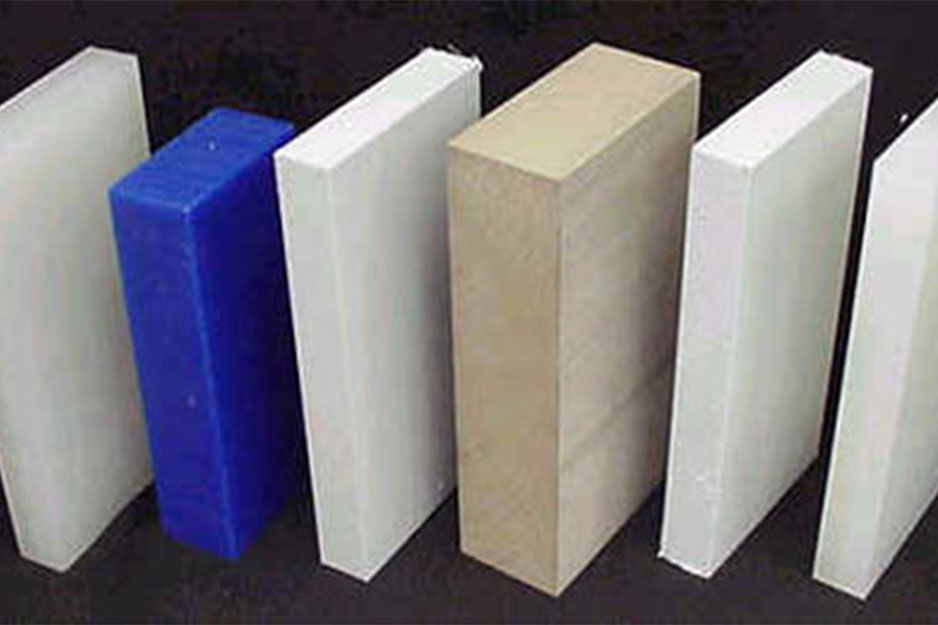

“Materials are available from hundreds of competing vendors, dramatically lowering material costs,” said McDonough. “We can even build our toothbrush prototypes in different colors, as well as different densities.”

A larger selection of materials to choose from makes it easier to create prototypes that meet FDA and other special government requirements, including UV resistance, bending strength, surface hardness, electrical conductivity, etc. This is particularly important for biomedical and food processing products, where biocompatibility and chemically inert properties are critical.