Natural-Looking Dental Restorations Produced with Digital Technology and Advanced Materials

Dr. Richard Rodriguez Part 1 | Caracas, Venezuela

Dr. Richard Rodriguez of Caracas, Venezuela, has extensive experience in implants and prosthesis, and a long career in the digital world. Dr. Rodriguez talks about his experience working with digital dental technology, the evolution of the materials involved, and the great benefits these techniques offer to dental labs and patients.

“The evolution of materials used for implants and prosthetics has been just incredible. Materials are constantly increasing their strength and durability so patients have restorations that are not just simple prosthetics but natural-like teeth. All of this is due to manufacturers, who help us give outstanding results in our offices”

After thoroughly researching the digital dental technology market, Dr. Rodriguez chose to work with CAD/CAM technology, which allows him to optimize both his time and the quality of his results.

Evolution of Materials for Implants and Prosthetics

“The evolution of materials used for implants and prosthetics has been just incredible. Materials are constantly increasing their strength and durability so patients have restorations that are not just simple prosthetics but natural-like teeth. All of this is due to manufacturers, who help us give outstanding results in our offices,” says Dr. Rodriquez.

These materials include zirconium silicate, lithium disilicate and nano-resins, as well as polymers and reinforced fiberglass. Currently, dentists have many materials to choose from, depending on the specific case and considering such factors as occlusion, the space required, and a patient’s age, among others.

Creating a Restoration

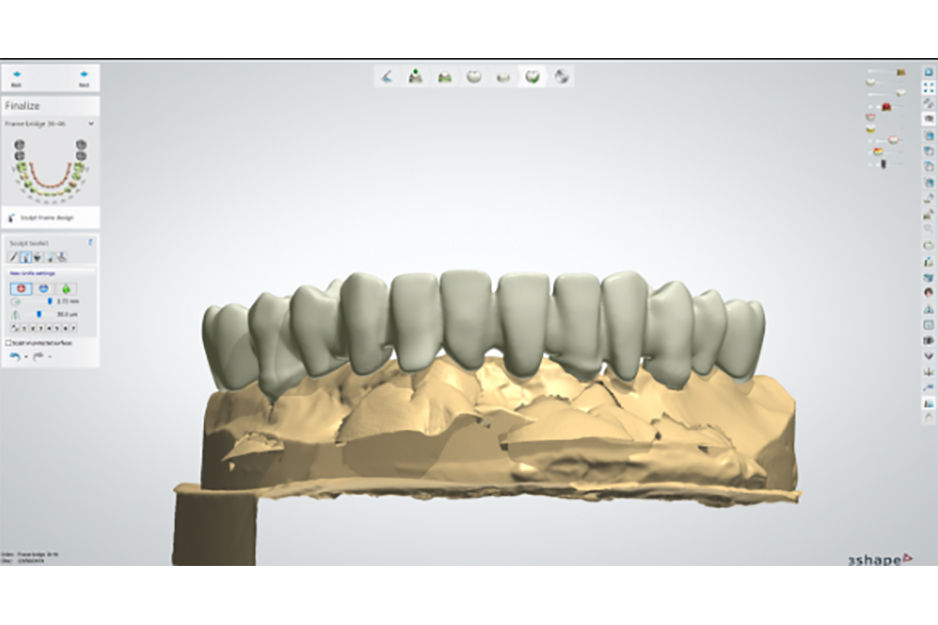

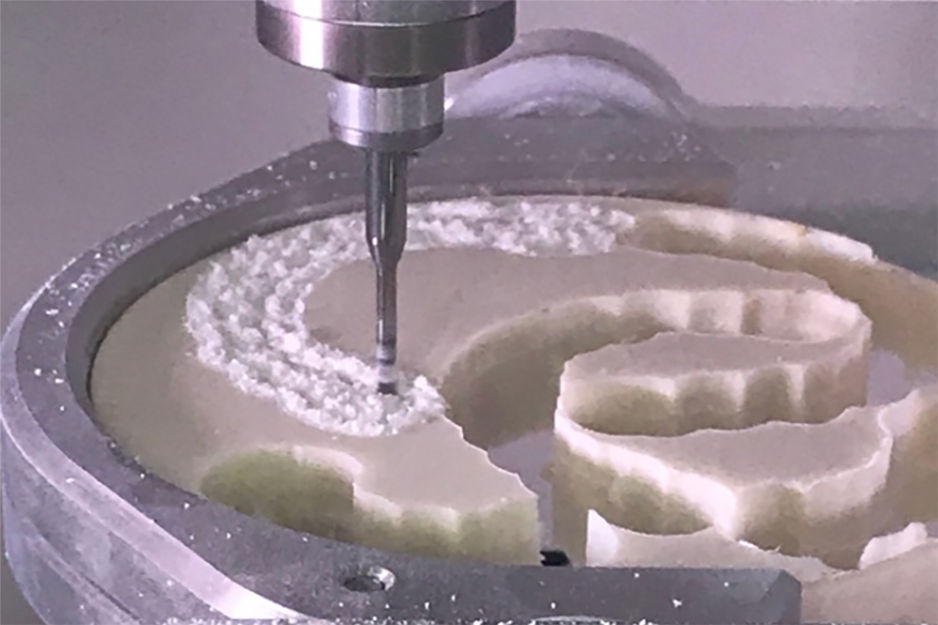

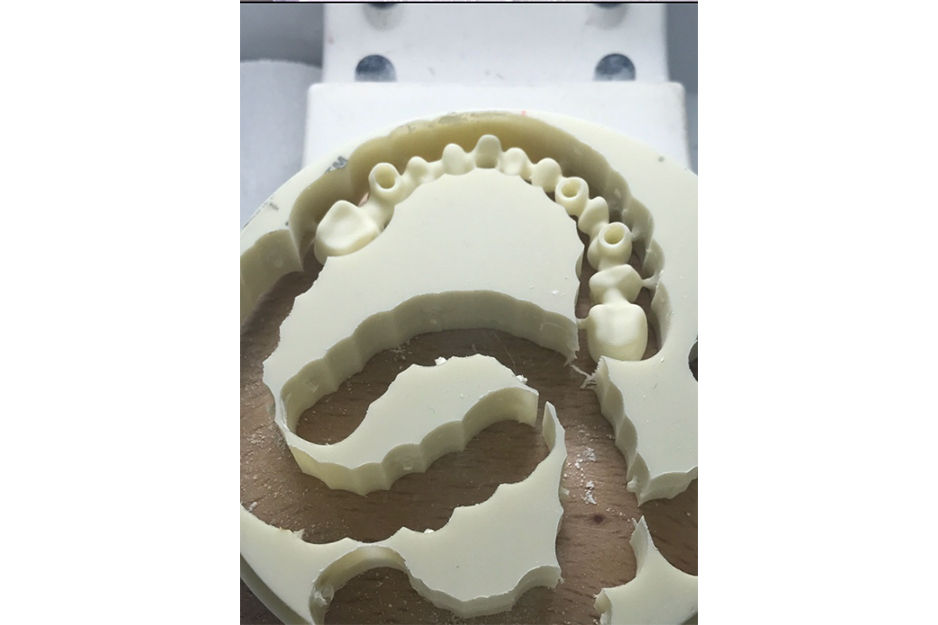

After obtaining a mold, either from natural teeth or implants, a technician digitizes it using a desktop scanner. After scanning, Dr. Rodriguez and his team create a design using CAD software, and later send it for processing and milling using the CAM software. The TRINIA substructure milling process takes approximately 50 minutes, after which the technician removes the block from the milling machine, ready to be prepared with acrylic teeth and gums.

For either fixed or removable prosthetics, with dental milling technology, dentists are able to offer patients products with longer duration and better aesthetics, fit and comfort.

Dr. Rodriguez talked to us about a dental case study of an edentulous patient he had a while ago, for whom he designed and created an aesthetic, comfortable and fully functional prosthesis using the Roland DG DGSHAPE DWX-51D dental mill.