Los Equipos de Fresado Digital Producen Soluciones Odontológicas Simples y Complejas

Universidad de Rochester | Rochester, New York

El Dr. Carlo Ercoli, del Instituto Eastman de Salud Oral (EIOH por sus siglas en inglés) en la Universidad de Rochester, no solo es presidente y director del Programa de Capacitación de Postgraduados de Prostodoncia, sino también un especialista tanto en prostodoncia como periodoncia. Además, él realiza trabajos de investigación y atiende a pacientes en la clínica del instituto. “Mi experiencia me permite una vista panorámica del proceso odontológico”, dice.

“Creo que la excelente calidad y precio razonable de las fresadoras Roland DG las hacen una buena inversión para cualquier laboratorio o entorno clínico”.

Instalación de Tecnología de Última Generación

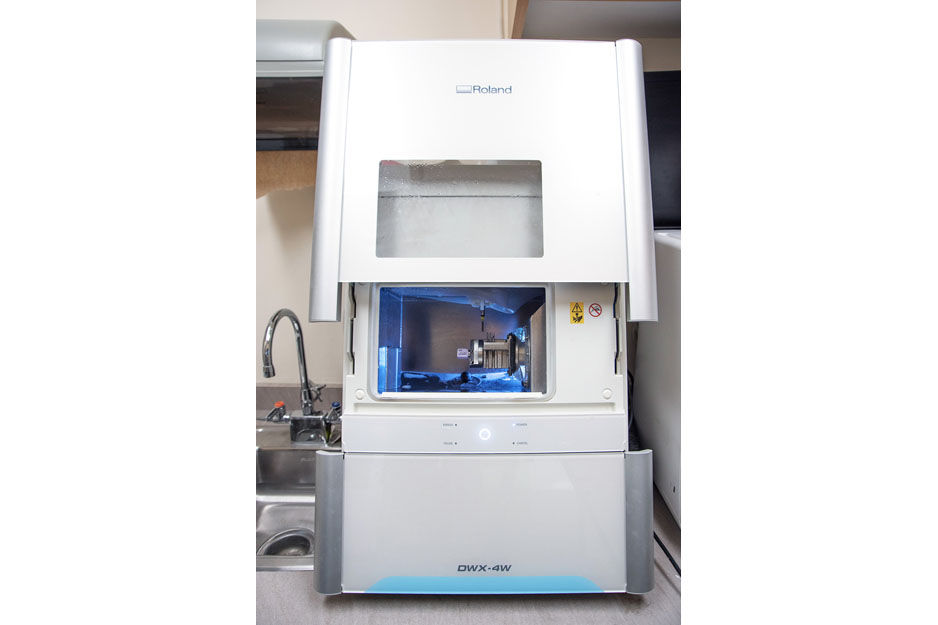

EIOH obtuvo su primera fresadora dental Roland DG en el 2012. Hoy en día, el laboratorio cuenta con tanto la fresadora dental de cinco ejes DWX-51D como con la fresadora dental en húmedo DWX-4W, las cuales fueron prestadas al Departamento para contribuir con la educación de los internos.

Las clínicas EIOH reciben aproximadamente 150.000 visitas anualmente. Además de los clientes de Rochester y comunidades aledañas, el Dr. Ercoli y sus colegas también trabajan con el Strong Memorial Hospital de la Universidad para atender a los pacientes ahí. “Podemos tratar todo, desde un diente levemente dañado hasta un reemplazo total de quijada”, dice.

La clínica usa sus dos fresadoras dentales Roland DG para producir la mayoría de sus restauraciones. “Creo que la excelente calidad y precios asequibles de las fresadoras Roland DG las hacen una buena inversión para cualquier laboratorio o entorno clínico”, dice el Dr. Ercoli.

La mayoría de las restauraciones producidas en EIOH son fijas, pero el 30% de éstas son desmontables. Además, la unidad de dispositivos dentales de la clínica también trabaja con el laboratorio de trastornos de sueño de la Universidad para producir tanto protectores nocturnos como dispositivos contra el apnea del sueño.

Preparación con Precisión

“Tanto la DWX-51D como la DWX-4W son muy precisas, y requieren muy poco mantenimiento”, dice el Dr. Ercoli. “Al estar equipados con fresadoras tanto en seco como en húmedo, podemos trabajar casi cualquier tipo de restauración fresada”.

El Dr. Ercoli estima que las producciones de restauración fresada de la EIOH está dividida de forma equitativa entre las fresadoras en seco y húmedo. La DWX-51D permite un fresado de cinco ejes de zirconio, cera, polimetilmetacrilato (PMMA), resina compuesta, poliéter éter cetona (PEEK) y yeso; mientras que la DWX-4W permite el fresado en húmedo de cerámica de vidrio y resinas compuestas tales como disilicato de litio.

En años recientes, la clínica EIOH ha incorporado un flujo digital que reduce significativamente los tiempos de ciclos de producción. “Los pacientes desean tener los beneficios de las más recientes tecnologías, y nosotros también”, dice el Dr. Ercoli. “Debido a que las fresadoras Roland DG tienen arquitectura abierta, nuestros programas de software de diseño y fabricación funcionan perfectamente”.