Creating Prosthetics Using MDX Technology

The Medical Arts Prosthetics Clinic | Dallas, Texas

How do you recreate patients' ears? "One at a time," said Allison Vest, MS, an anaplastologist with The Medical Art Prosthetics Clinic in Dallas, Texas. The Clinic specializes in prosthetics for fingers, toes and facial features. Patients afflicted by cancer, congenital conditions or trauma come to the clinic from all over the country and around the world to obtain highly personalized aesthetic restoration.

“I got into this field to make meaningful art that helps people improve the quality of their lives," said Vest. "The MDX scanning/milling machine helps me provide precise aesthetic restoration so our patients are comfortable in any situation.”

"I got into this field to make meaningful art that helps people improve the quality of their lives," said Vest. "The MDX scanning/milling machine helps me provide precise aesthetic restoration so our patients are comfortable in any situation."

The Medical Art Prosthetics Clinic is a full-service office, clinic and laboratory. Vest joined founder Greg Gion at Medical Art Prosthetics in 2004, bringing a balance of artistic talent and medical training as well as a command of digital technologies that are benefitting the field of facial and body restoration.

The Medical Arts Prosthetics Clinic invested in a Roland DG portable milling machine to assist them with auricular, or ear, restoration. They chose the MDX-15 because of its compact dimensions, easy-to use technology, and all-in-one capabilities. "The machine has paid for itself many times over," said Vest. "I can set it to scan overnight, and the next day can let it mill while I work on other tasks. "

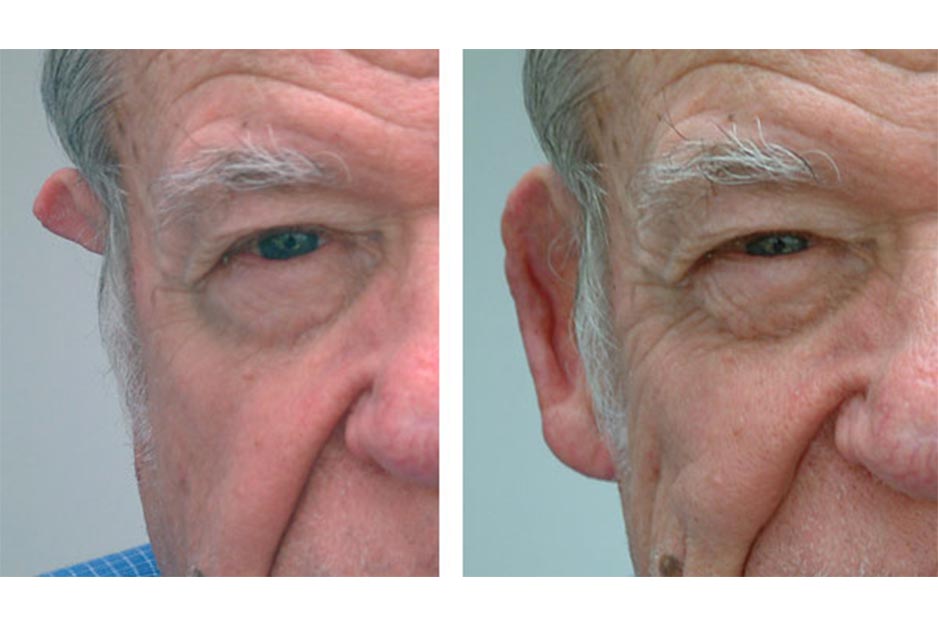

To create a prosthetic ear, Vest takes a mold of the patient's unaffected ear and scans it using the MDX's active piezo sensor, creating a digital file. The file is then mirror-imaged through the machine's software. Next, Vest installs the MDX's milling spindle and sets the machine to mill a wax cast of the prosthetic ear. "The milling accuracy is incredible. I use the .2 millimeter setting, which provides precise skin texture details," said Vest.

Vest then uses the milled wax cast to fabricate a prosthetic ear. "Before, I would heat a pot of wax and carve the ear by hand," said Vest. "The MDX creates a mirror image of the patient's existing ear with extreme accuracy, and allows me to focus on fitting and finishing the prosthesis. "