Forging Ahead with Roland DG's Flatbed Technology

The Forge | Huntington Beach, California

Luciano Martinez, who operates The Forge in Huntington Beach, Calif., has always believed that doing things in-house is best. “Why give that work to someone else?“ he said.

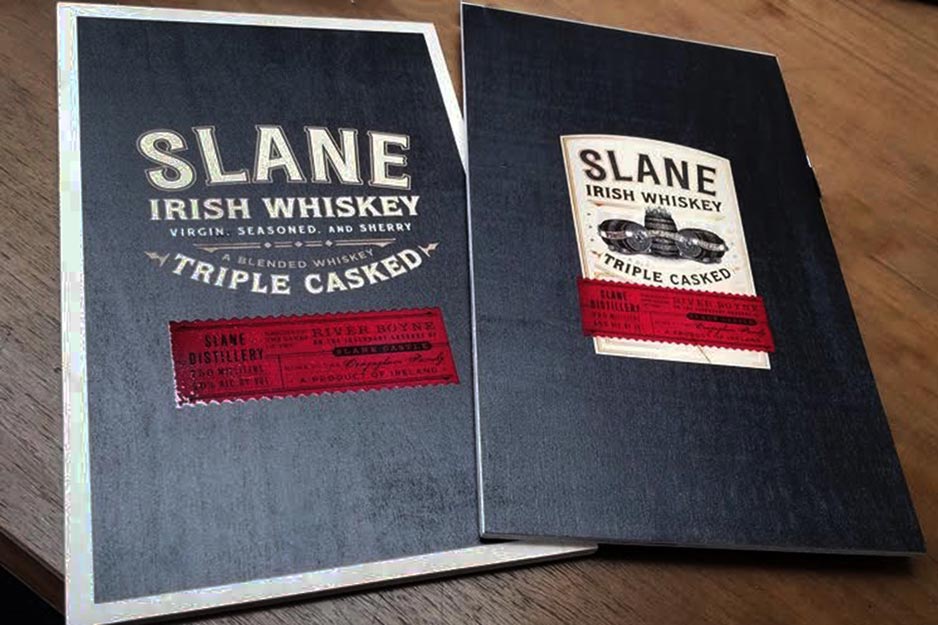

The Forge specializes in designing and creating custom promotional products and accessories for the action sports and distilled spirits industries. They create everything from belt buckles to retail displays, including giveaway items such as keychains, napkin caddies and barware.

The Forge has used its flatbed to print on metal, stainless steel, aluminum, acrylic, license plates, chalkboards stands for hotels – even corkboard. The Forge uses Roland DG’s ECO-UV inks exclusively to ensure optimum graphic results and ink efficiency.

The Forge has staff of eight, with several part-timers who come on as needed. The shop has expanded twice, growing from 1,600 square feet to 4,000 square feet.

“The hardest part is getting the customer in front of you. Once they’re there, you want to give them everything you can,” said Martinez. “With our Roland DGs, we’re ready to say yes.”

The Forge specializes in designing and creating custom promotional products and accessories for the action sports and distilled spirits industries. They create everything from belt buckles to retail displays, including giveaway items such as keychains, napkin caddies and barware.

Expanding Markets with Roland DG

Martinez began by using a Roland DG cutter to incorporate art and text into designs, models and molds. Later, Martinez purchased the Roland DG MDX-650A benchtop milling machine. “With the MDX, we could branch out to milling full models and molds from wood and acrylics,” he said.“Now we are a do-it-all shop. Even if it’s not something in our wheelhouse, we make it something in our wheelhouse.”

Martinez’s last step was being able to provide in-house printing and decoration. The Forge added the Roland DG VersaUV LEJ-640FT UV flatbed printer, which can print on materials up to six inches thick. “First of all, the LEJ-640FT was a Roland DG, so I knew I could count on it for quality and reliability, but it also has that high head clearance,” said Martinez.100,000 Reasons Why The Forge Chose the LEJ-640FT

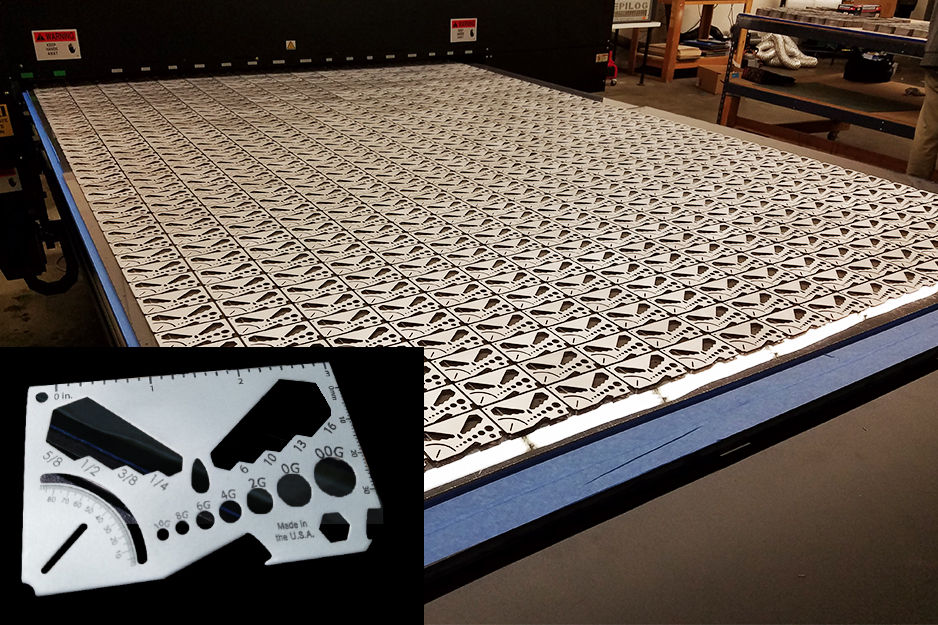

A major reason why The Forge chose the LEJ-640FT was its production capabilities. The Forge is known for producing just about anything out of metal, wood and other materials, so it needed an on-demand solution for printing onto many small items at once, as well as larger pre-manufactured items.

With a 64” x 98” print bed and a print speed of up-to 133 sqft/hr, it represented the ideal technology for fulfilling a specialized client order that required print customization of 100,000 metal tools within a tight deadline. Martinez described the LEJ-640FT’s unique qualities that made it the right choice for their business.

“It was the only machine on the market that suited our need to quickly print onto thousands of unique, specialty items.”

Flatbed Technology Handles Prototypes to Full Runs

Martinez appreciates that the LEJ -640FT handles everything from very small to very large runs, allowing both prototypes and full runs. “Now we are a do-it-all shop. Even if it’s not something in our wheelhouse, we make it something in our wheelhouse,” he said.The Forge has used its flatbed to print on metal, stainless steel, aluminum, acrylic, license plates, chalkboards stands for hotels – even corkboard. The Forge uses Roland DG’s ECO-UV inks exclusively to ensure optimum graphic results and ink efficiency.

“The hardest part is getting the customer in front of you. Once they’re there, you want to give them everything you can,” said Martinez. “With our Roland DGs, we’re ready to say yes.”