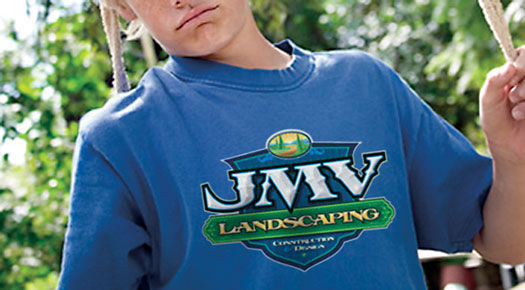

If you’re already using digital print/cut technology, it’s easy to get started in the custom apparel market. One of the biggest selling points is the full-color printing capabilities.

With digital printing you’re not limited by spot colors, so you have the freedom to include as much detail as you want in a design. You can use the same image files created for other digital printing projects without having to reconstruct them for screen printing. There are no screen charges or setup fees, so pricing is competitive on full-color short-run work. You also have the benefit of true photo-realistic printing. The ability to contour cut avoids the “square-block” look and avoids unnecessary background.

All you need to get started is your printer/cutter and specialized media called heat transfer material. Roland DG sells a Heat Transfer Material called HeatSoft Heat Transfer Material (HTM2). HTM2 is specifically designed for inkjet transfers to cotton or cotton blend garments, which makes it ideal for T-shirts, sweatshirts, bags, hats and other fabric items. HTM2 is an opaque media, which means you can use it on dark garments as well as light ones. It works with a wide variety of ink types including pigment and mild solvent inks. HTM2 prints and cuts very well and delivers outstanding color saturation.

You’ll need to find a good wholesale apparel supplier. They’ll usually have a catalog you can use to help clients select the right garments for their job. You should probably get a heat press, as well. Customers have tried using an iron, but it doesn’t work very well.

PRODUCING CUSTOM APPAREL DECORATION

To create custom apparel with your inkjet printer/cutter and HTM2, you can use the following workflow:

-

Setup your artwork with print data and cut paths.

- Send the artwork to the print/cut device for printing and cutting on heat transfer material (HTM2). (Fig. 1) Be sure to use the appropriate color-management profiles for HTM2 media. The colors of the printed image will appear somewhat subdued on the media, but will appear fully saturated upon transfer.

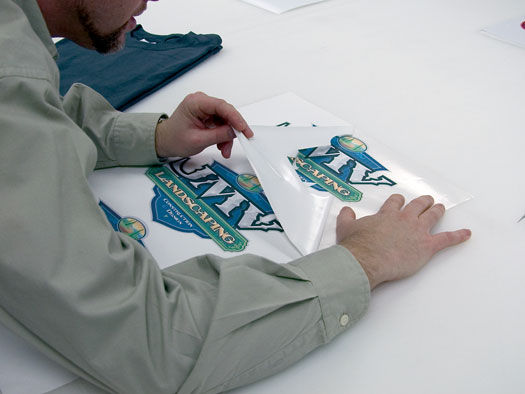

- Weed excess vinyl away from the graphic. (Fig. 2)

- Mask the graphic using the Polyester Transfer Mask. This will keep the graphic from being distorted and keep multi-piece graphics assembled correctly.

-

Clean your blank garment with a lint roller or brush. This will pick up any loose materials or fibers that can cause discoloration and spotting when the garment is heat pressed.

- Preheat the heat press to the recommended temperature setting. For Roland DG’s HTM2 product, set it for 350 Fahrenheit. Place the garment flat on the press and briefly prepress the area where you want to apply the transfer to smooth away any wrinkles.

- Position the printed, cut and masked image on top of the garment. (Fig. 3)

-

Press the image and the garment according to the recommended time and temperature settings (for Roland DG’s HTM2 product use 12-15 seconds). Using the correct time and temperature settings are critical for a successful heat transfer.

- Carefully remove the mask to reveal a bright and durable finished product (Fig. 4).

To see this process in action, watch the video: Creating Custom Apparel with HeatSoft Transfer Material.

That’s all there is to it. In no time, you’ll be producing custom color apparel that knocks ‘em dead.

This article has been adapted from Roland DG’s popular instructional booklet, Taking the Mystery Out of Print/Cut. The ultimate guide to print/cut technology, this valuable, information-packed resource has already helped thousands of Roland DG's customers streamline their production environments and grow their businesses. For a quick look, watch this short video.