One of the great perks of being a Roland DGA employee is the access we have to all the magical technology that Roland DG has at our head office in Irvine, California. This is especially useful during back-to-school season, when students need new custom uniforms and school pride clothing for their sports teams, cheer squads, and clubs.

School Pride Sock Idea

When my daughter told me that her back-to-school “cheer sister” gift this year was on the theme of “socks” and she couldn’t find anything cute, I suggested making use of our amazing Roland DG technology to make some custom cheer socks in her team colors that her cheer sister could wear with ultimate school pride. My daughter loved the idea, especially since personalized clothing with school logos and colors is so much more popular than generic items in high schools.

Using a little bit of design know-how and with user friendly Roland DG printers and software, I found the whole prep and print process far easier than I had anticipated.

Dye-Sublimation Printing Your Digital Design

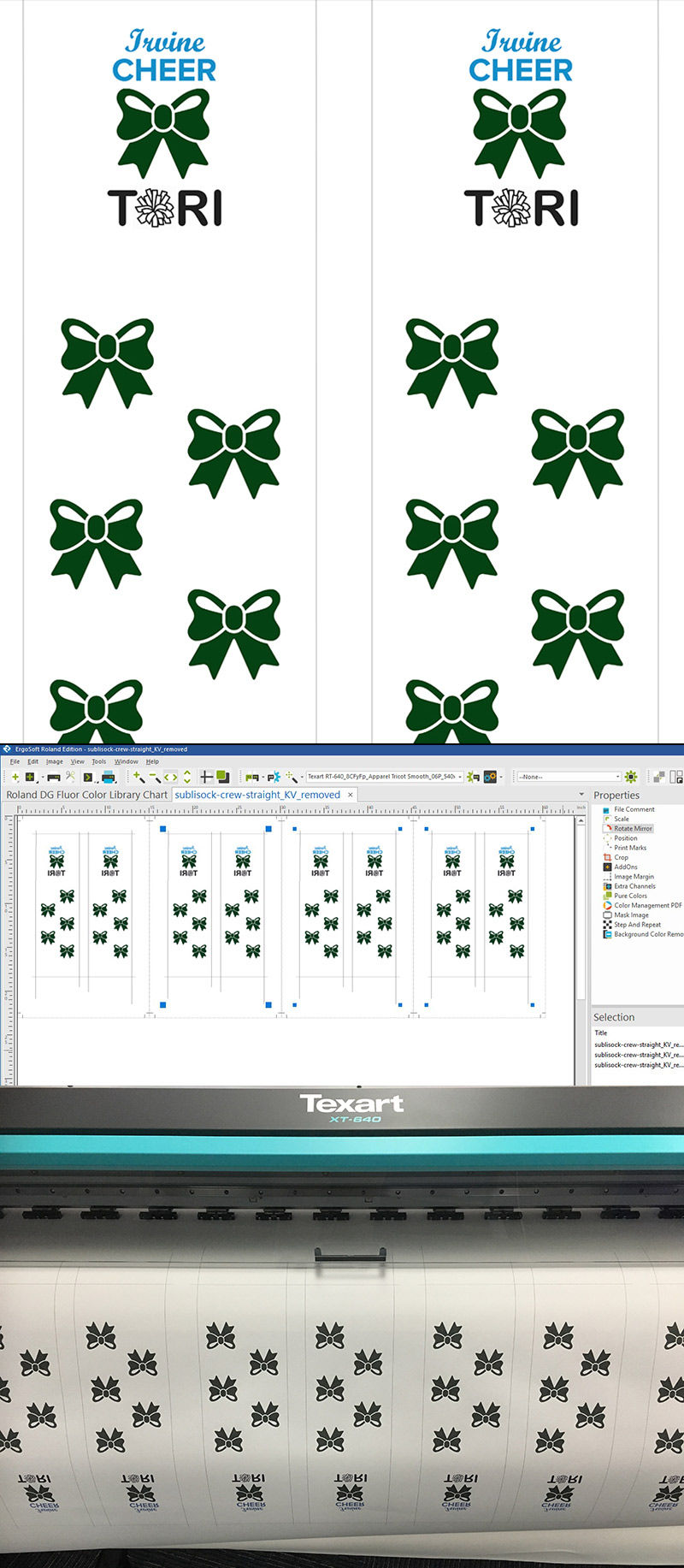

After downloading the relevant online sock template as a design guide, I opened the template in Photoshop (PSD) and created a fun design with school colors and personalized text. I then saved the Photoshop file as a PDF and uploaded it to Ergosoft Roland DG Edition Software for RIP and print to our Texart XT-640 dye-sublimation printer.

Using Ergosoft Roland DG Edition Software was surprisingly easy. After uploading the design to the software, I mirrored (flipped) the design* and added a step & repeat function to maximize the print area and printed a short run of the sock design— I would need four designs in total for the front and back of the socks. Finally, I trimmed the print sheet into individual sock designs to prep them for the heat-transfer process.

*It’s important to flip the design during dye-sublimation— designs are heat pressed “face-onto” the fabric.Prepping for Heat Transfer

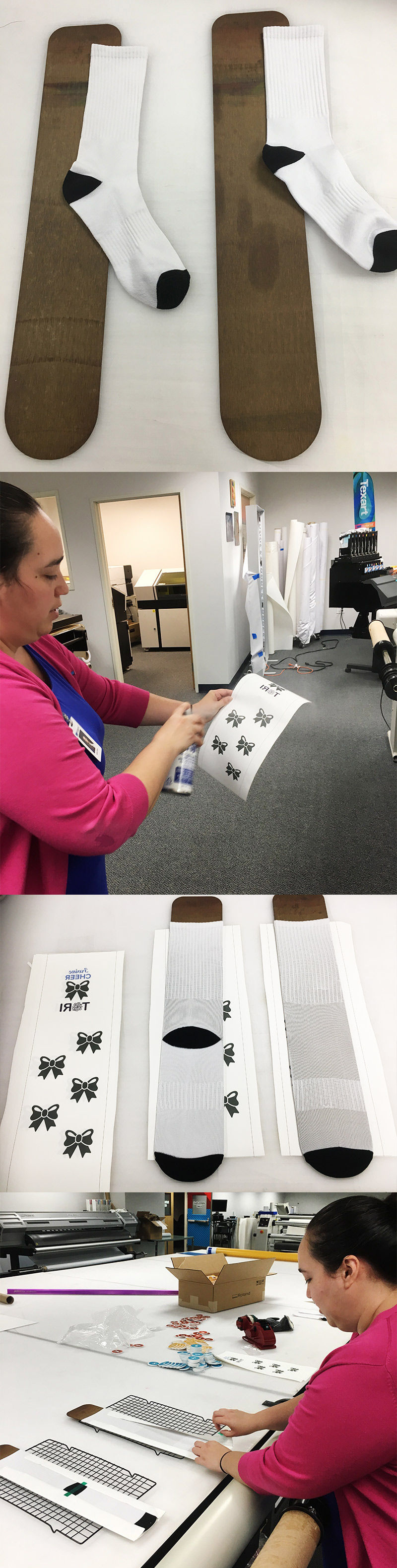

The socks I used for the project were polyester-based sock blanks. These can be purchased from many online suppliers that specialize in dye-sublimation blank products. To correctly prep the socks, I did the following:

- Stretched the socks over special fixtures to give the socks a surface area to print onto

- Lightly tacked the face of the sock-prints with heat-transfer spray adhesive

- Put them face-down on the socks— taping the edges with special heat resistant tape

Heat Transferring the Design onto Socks

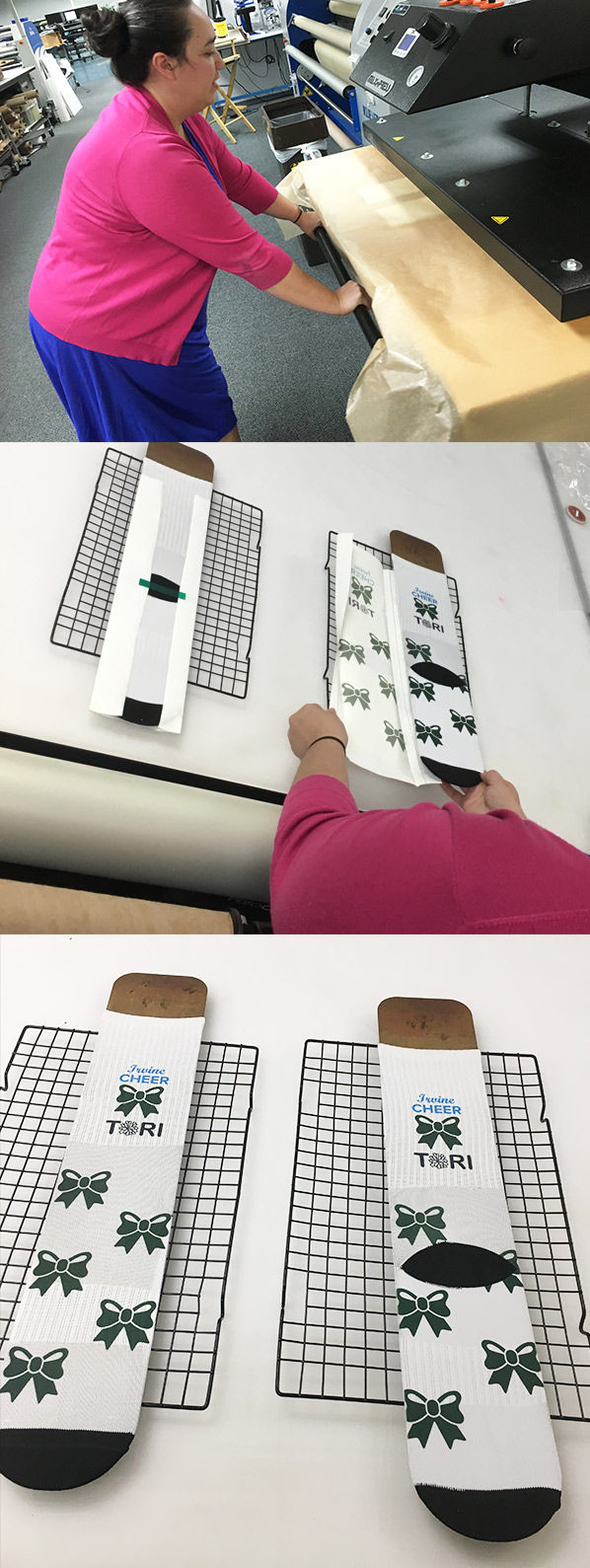

While prepping the socks, I heated the heat press machine until it reached 370˚. The next stage in the process was adding the socks to the heat press to transfer the design onto the fabric. I used the following heat press procedure to transfer my design:

- Placed the socks “paper down” on the flatbed and covered with heat-resistant paper

- Closed the flatbed for about 30 seconds until the flatbed “beeped” and automatically opened

- Allowed the socks to cool before moving them to the desk and carefully removing the transfer paper from the socks

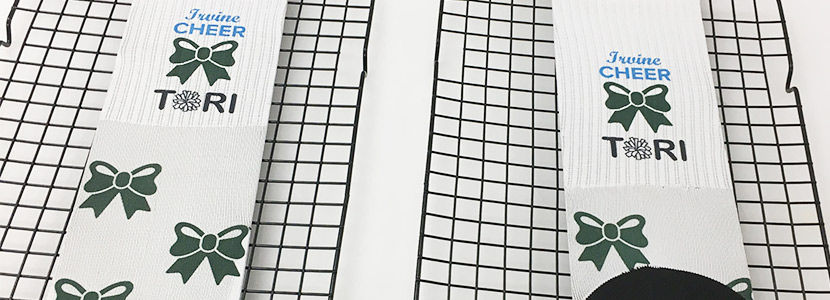

After repeating the process for the other side, I had completed the custom socks and they looked exactly how I had envisioned them. I also have a better understanding of the print and application methods that our school inplant, sign shop, and customization customers use to produce custom socks, jerseys, bags, and other school sportswear each year at back-to-school time. My daughter was thrilled with the result, and so was her cheer sister who received a personal and meaningful gift from her teammate.

- If you’d like to find out more about Roland DG dye-sublimation machines and workflows, download our dye-sublimation printing guide to see how you can build a custom sportswear or apparel business with a choice of Roland DG machines.