If you’re experiencing problems with contour cut quality when operating a Roland DG printer/cutter, there’s a good chance that you’re dealing with one of two common issues.

For problems with print/cut registration, the first thing we look for is whether or not the pinch roller wheels are accurately gripping the media. Two factors seem to pop up frequently, but they can be easily avoided:

A. The user leaves all of the pinch roller wheels in during print and cut jobs and the media curls. As a result, the wheels run over the curled media and can ruin the cut job. (Side problem: roller wheels get covered in ink!)

Solution: Make sure to remove pinch roller wheels for print/cut jobs unless setting a dry time of 15 minutes or more.

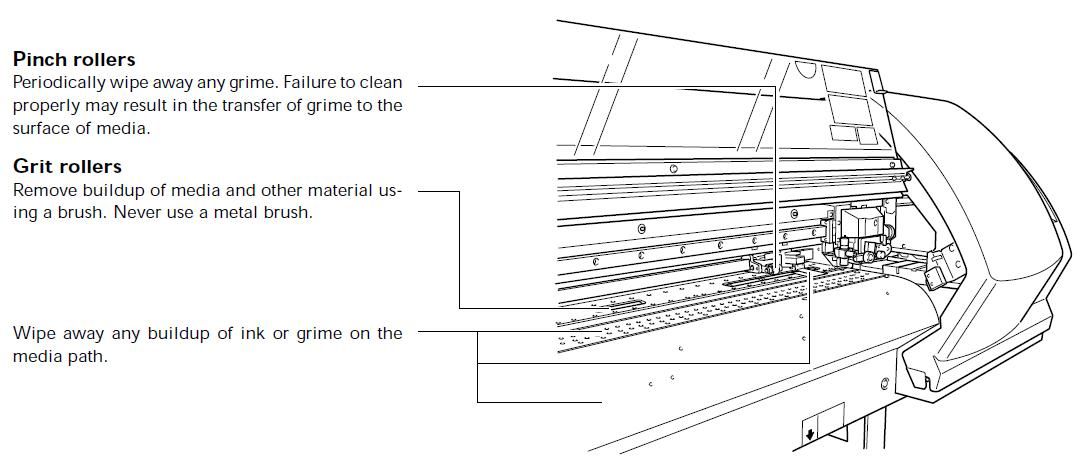

B. Debris has built up on the grit roller and the grit roller cannot correctly grip the release liner of the substrate.

Solution: Use a stiff bristle brush or a toothbrush and periodically clean the grit roller to eliminate debris. A shop vac is also useful for removing paper left over from perfcut and sheet cuts (Note: Never use compressed air to blow out debris!).